Page 146 - Fluid Power Engineering

P. 146

120 Cha pte r F o u r

against the pressures inside the pumping chambers. Because of this,

an optimum clearance between the rotor and the side plates is guaran-

teed, and the side clearance leakage is minimized.

Tip Clearance Leakage

The tip clearance leakage takes place through the clearance between

the blade tip and the inner surface of the cam ring. Therefore, the

blade root should be pressurized wherever the blade separates two

chambers of different pressure (see Fig. 4.34c and 4.34d). Otherwise,

wherever the blade separates two chambers of equal pressure, the

blade root should have the same pressure as that in these chambers

(see Fig. 4.34a and 4.34b). In this way, the blade is pressure balanced

and is pushed radially outwards under the action of the centrifugal

force only. This zone of blade displacement has minimal friction and

reduced wear.

Most of the pressure-balanced vane pumps have an intra-vane

feature. This design helps keep the vane in continuous contact with

the cam ring during the rises and falls while minimizing the vane-tip

contact force. The construction of the intra-vane structure is illustrated

in Fig. 4.32. Instead of a single vane, there are two vanes of the same

thickness. A smaller one (intra vane 6) is installed at the inner side of

the main vane (4), which creates an inner chamber (intra-vane cham-

ber) between them (5).

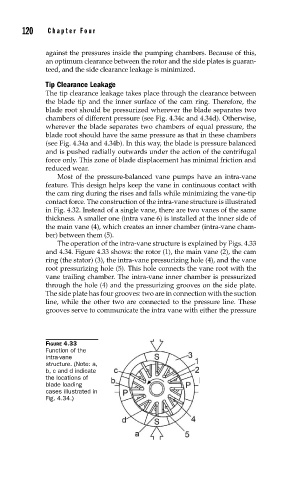

The operation of the intra-vane structure is explained by Figs. 4.33

and 4.34. Figure 4.33 shows: the rotor (1), the main vane (2), the cam

ring (the stator) (3), the intra-vane pressurizing hole (4), and the vane

root pressurizing hole (5). This hole connects the vane root with the

vane trailing chamber. The intra-vane inner chamber is pressurized

through the hole (4) and the pressurizing grooves on the side plate.

The side plate has four grooves: two are in connection with the suction

line, while the other two are connected to the pressure line. These

grooves serve to communicate the intra vane with either the pressure

FIGURE 4.33

Function of the

intra-vane

structure. (Note: a,

b, c and d indicate

the locations of

blade loading

cases illustrated in

Fig. 4.34.)