Page 92 - Fluid Power Engineering

P. 92

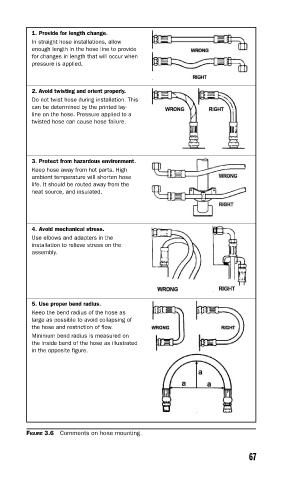

1. Provide for length change.

In straight hose installations, allow

enough length in the hose line to provide

for changes in length that will occur when

pressure is applied.

2. Avoid twisting and orient properly.

Do not twist hose during installation. This

can be determined by the printed lay-

line on the hose. Pressure applied to a

twisted hose can cause hose failure.

3. Protect from hazardous environment.

Keep hose away from hot parts. High

ambient temperature will shorten hose

life. It should be routed away from the

heat source, and insulated.

4. Avoid mechanical stress.

Use elbows and adapters in the

installation to relieve stress on the

assembly.

5. Use proper bend radius.

Keep the bend radius of the hose as

large as possible to avoid collapsing of

the hose and restriction of flow.

Minimum bend radius is measured on

the inside bend of the hose as illustrated

in the opposite figure.

FIGURE 3.6 Comments on hose mounting.

67