Page 93 - Fluid Power Engineering

P. 93

68 Cha pte r T h ree

6. Secure for protection.

Install hose runs to avoid rubbing or

abrasion. Use hose clamps to support

long runs of hose or to keep hose away

from moving parts. It is important that

the clamps not allow the hose to move

in order to avoid abrasion and premature

hose failure.

7. Avoid improper hose movement.

Make sure the relative motion of the

machine components produces bending

rather than twisting of the hose. Hose

should be routed so the flex is in the

same plane as the equipment movement.

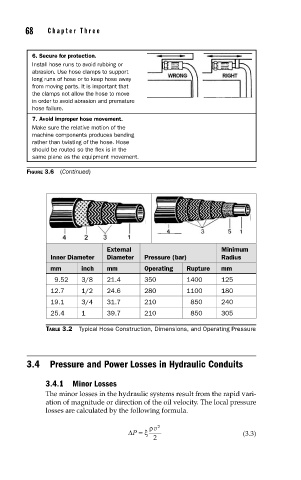

FIGURE 3.6 (Continued)

External Minimum

Inner Diameter Diameter Pressure (bar) Radius

mm inch mm Operating Rupture mm

9.52 3/8 21.4 350 1400 125

12.7 1/2 24.6 280 1100 180

19.1 3/4 31.7 210 850 240

25.4 1 39.7 210 850 305

TABLE 3.2 Typical Hose Construction, Dimensions, and Operating Pressure

3.4 Pressure and Power Losses in Hydraulic Conduits

3.4.1 Minor Losses

The minor losses in the hydraulic systems result from the rapid vari-

ation of magnitude or direction of the oil velocity. The local pressure

losses are calculated by the following formula.

ρ v 2

ΔP =ξ (3.3)

2