Page 115 - Fluid mechanics, heat transfer, and mass transfer

P. 115

FLOW MEASUREMENT

92

multiple pistons or pulsation dampening reservoirs & These applications involve accurate measurement

are installed. of volumetric flow ratios to be maintained

& Because of the close tolerances of the piston and between the process liquid volume and the chemical

cylinder sleeve, a flushing mechanism must be pro- injection volume. Examples include injection, or

vided in abrasive applications. introduction, of

& Piston pumps are sized on the basis of the displace- ➢ Sodium hypochlorite disinfectant into water.

ment of the piston and the required flow rate and ➢ Fertilizer into irrigation water.

discharge pressure. ➢ Bioengineered organisms into liquids for manu-

& Check valves (or, on critical applications, double facturing products such as soaps for large laun-

check valves) are selected to protect against reverse dries, defoaming chemicals, and insecticides.

flow. . What is an oval gear flow meter? What are its

& Diaphragm pumps are the most common industrial applications?

PD pumps. A typical configuration consists of a & An oval gear flow meter consists of two oval-shaped,

single diaphragm, a chamber, and suction and dis- fine-toothed gear rotors, one mounted vertically and

charge check valves to prevent reverse flow. the other horizontally, with gears meshing at the tip of

& The piston can either be directly coupled to the the vertical gear and the center of horizontal gear that

diaphragm or can force a hydraulic oil to drive the rotate within a chamber of specified geometry.

diaphragm. & The two rotors rotate opposite to each other, creating

& Maximum output pressure is about 8.6 barg an entrapment in the crescent-shaped gap between

(125 psig). the housing and the gear.

& Variations include bellows type diaphragms, hydrau- & As these rotors turn, they sweep out and trap a very

lically actuated double diaphragms, and air operated, precise volume of fluid between the outer oval shape

reciprocating double diaphragms. of thegears and the inner chamber walls, with none of

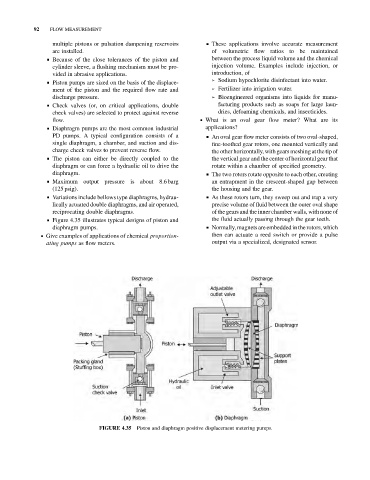

& Figure 4.35 illustrates typical designs of piston and the fluid actually passing through the gear teeth.

diaphragm pumps. & Normally, magnets are embedded in the rotors, which

. Give examples of applications of chemical proportion- then can actuate a reed switch or provide a pulse

ating pumps as flow meters. output via a specialized, designated sensor.

Piston and diaphragm positive displacement metering pumps.

FIGURE 4.35