Page 112 - Fluid mechanics, heat transfer, and mass transfer

P. 112

FLOW MEASUREMENT 89

& The maximum allowable pressure drop across the & Meters with rubber disks give better accuracy

meter constrains the maximum operating flow in than metal disks due to the better sealing they

high-viscosity services. provide.

& Wear rapidly destroys their accuracy. For this reason, & Nutating disk meters are available in sizes from 1.6 to

PD meters are generally not recommended for mea- 5 cm (five-eighth to 2 in.). They are suited for 10 barg

suring slurries or abrasive fluids. (150 psig) operating pressures with overpressure to a

& The process fluid must be clean. Particles greater than maximum of 20 barg (300 psig). Cold-water service

100 mm in size must be removed by filtering. units are temperature limited to 50 C. Hot-water

units are available up to 120 C.

& In clean fluid services, their precision and wide

rangeability make them ideal for custody transfer & The accuracy of these meters is required to be 2%

and batch charging. of actual flow rate.

& They are most widely used as household water meters. & Higher viscosity can produce higher accuracy, while

lower viscosity and wear over time will reduce

& In industrial and petrochemical applications, PD

accuracy.

meters are commonly used for batch charging of

both liquids and gases. . Describe a rotating vane PD flow meter and illustrate it.

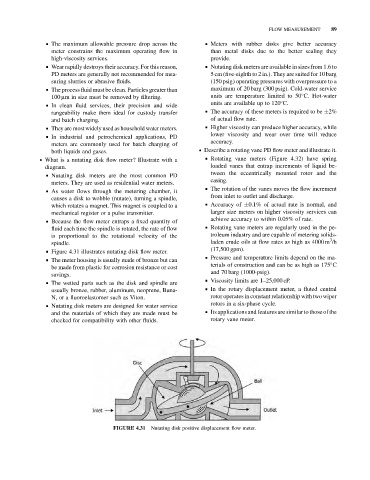

. What is a nutating disk flow meter? Illustrate with a & Rotating vane meters (Figure 4.32) have spring

diagram. loaded vanes that entrap increments of liquid be-

tween the eccentrically mounted rotor and the

& Nutating disk meters are the most common PD

casing.

meters. They are used as residential water meters.

& The rotation of the vanes moves the flow increment

& As water flows through the metering chamber, it

from inlet to outlet and discharge.

causes a disk to wobble (nutate), turning a spindle,

which rotates a magnet. This magnet is coupled to a & Accuracy of 0.1% of actual rate is normal, and

mechanical register or a pulse transmitter. larger size meters on higher viscosity services can

achieve accuracy to within 0.05% of rate.

& Because the flow meter entraps a fixed quantity of

fluid each time the spindle is rotated, the rate of flow & Rotating vane meters are regularly used in the pe-

is proportional to the rotational velocity of the troleum industry and are capable of metering solids-

3

spindle. laden crude oils at flow rates as high as 4000 m /h

(17,500 gpm).

& Figure 4.31 illustrates nutating disk flow meter.

& Pressure and temperature limits depend on the ma-

& The meter housing is usually made of bronze but can

terials of construction and can be as high as 175 C

be made from plastic for corrosion resistance or cost

and 70 barg (1000-psig).

savings.

& Viscosity limits are 1–25,000 cP.

& The wetted parts such as the disk and spindle are

usually bronze, rubber, aluminum, neoprene, Buna- & In the rotary displacement meter, a fluted central

N, or a fluoroelastomer such as Viton. rotor operates in constant relationship with two wiper

rotors in a six-phase cycle.

& Nutating disk meters are designed for water service

and the materials of which they are made must be & Its applications and features are similar to those of the

checked for compatibility with other fluids. rotary vane meter.

Nutating disk positive displacement flow meter.

FIGURE 4.31