Page 116 - Fluid mechanics, heat transfer, and mass transfer

P. 116

FLOW MEASUREMENT 93

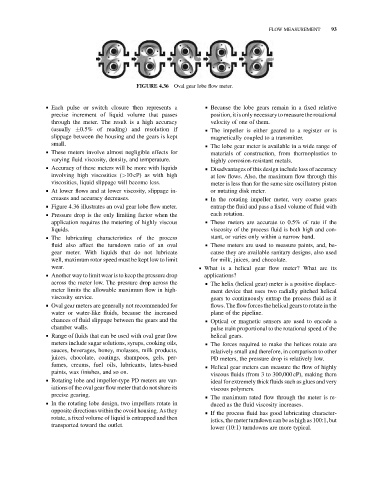

Oval gear lobe flow meter.

FIGURE 4.36

& Each pulse or switch closure then represents a & Because the lobe gears remain in a fixed relative

precise increment of liquid volume that passes position, it is only necessary to measure the rotational

through the meter. The result is a high accuracy velocity of one of them.

(usually 0.5% of reading) and resolution if & The impeller is either geared to a register or is

slippage between the housing and the gears is kept magnetically coupled to a transmitter.

small. & The lobe gear meter is available in a wide range of

& These meters involve almost negligible effects for

materials of construction, from thermoplastics to

varying fluid viscosity, density, and temperature. highly corrosion-resistant metals.

& Accuracy of these meters will be more with liquids & Disadvantages of this design include loss of accuracy

involving high viscosities (>10 cP) as with high at low flows. Also, the maximum flow through this

viscosities, liquid slippage will become less. meter is less than for the same size oscillatory piston

& At lower flows and at lower viscosity, slippage in- or nutating disk meter.

creases and accuracy decreases. & In the rotating impeller meter, very coarse gears

& Figure 4.36 illustrates an oval gear lobe flow meter. entrap the fluid and pass a fixed volume of fluid with

& Pressure drop is the only limiting factor when the each rotation.

application requires the metering of highly viscous & These meters are accurate to 0.5% of rate if the

liquids. viscosity of the process fluid is both high and con-

& The lubricating characteristics of the process stant, or varies only within a narrow band.

fluid also affect the turndown ratio of an oval & These meters are used to measure paints, and, be-

gear meter. With liquids that do not lubricate cause they are available sanitary designs, also used

well, maximum rotor speed must be kept low to limit for milk, juices, and chocolate.

wear. . What is a helical gear flow meter? What are its

& Another way to limit wear is to keep the pressure drop applications?

across the meter low. The pressure drop across the & The helix (helical gear) meter is a positive displace-

meter limits the allowable maximum flow in high- ment device that uses two radially pitched helical

viscosity service. gears to continuously entrap the process fluid as it

& Oval gear meters are generally not recommended for flows. The flow forces the helical gears to rotate in the

water or water-like fluids, because the increased plane of the pipeline.

chances of fluid slippage between the gears and the & Optical or magnetic sensors are used to encode a

chamber walls. pulse train proportional to the rotational speed of the

& Range of fluids that can be used with oval gear flow helical gears.

meters include sugar solutions, syrups, cooking oils, & The forces required to make the helices rotate are

sauces, beverages, honey, molasses, milk products, relatively small and therefore, in comparison to other

juices, chocolate, coatings, shampoos, gels, per- PD meters, the pressure drop is relatively low.

fumes, creams, fuel oils, lubricants, latex-based & Helical gear meters can measure the flow of highly

paints, wax finishes, and so on.

viscous fluids (from 3 to 300,000 cP), making them

& Rotating lobe and impeller-type PD meters are var-

ideal for extremely thick fluids such as glues and very

iations of the oval gear flow meter that do not share its viscous polymers.

precise gearing. & The maximum rated flow through the meter is re-

& In the rotating lobe design, two impellers rotate in

duced as the fluid viscosity increases.

opposite directions within the ovoid housing. As they & If the process fluid has good lubricating character-

rotate, a fixed volume of liquid is entrapped and then

istics, the meter turndown can be as high as 100:1, but

transported toward the outlet.

lower (10:1) turndowns are more typical.