Page 287 - Fluid mechanics, heat transfer, and mass transfer

P. 287

CONVECTIVE HEAT TRANSFER BASICS

268

. How dissolved oxygen buildup can occur in power plant Vacuum is created by the use of steam jet ejectors

condenser systems? or liquid ring vacuum pumps.

& Cold makeup water with high solubility for oxygen is . Why it is necessary to remove/control dissolved salts

a major source. from boiler feed water?

& Air leakages into the system under lower condenser & Dissolved salts in the feed water get concentrated in

pressures. the water inside the boiler leading to scale formation

& High vapor loads in vent systems resulting in insuf- and corrosion of metal surfaces. The net result will be

ficient vent capacity. lowering the efficiency of steam generation, besides

damage to boiler due to corrosion.

& High air ingress occurs at start-up and reduced loads.

It can occur between hot condensate well and the & The feed water is demineralized by reverse osmosis

condensate pump. or other methods and concentrations of remaining

solids in the water inside the boiler are controlled

. How is air ingress into the condensate system pre-

from excessive increases by blowdown. High dis-

vented/reduced? Illustrate.

solved solids content can also increase foaming

& By preheating makeup water with turbine exhaust

tendency and carry over of the solids with the steam,

steam and passing the preheated water through a

which will increase scale formation in the heat

packed bed or other deaerator of suitable design

transfer equipment.

before it enters the condenser and mixes with the

& The total dissolved solids (TDS) in the water in the

condensate.

boiler should be kept below 3000 mg/L, which is

& Prevention of oxygen absorption can be accom-

achieved by blowdown.

plished by designing the condenser internals to per-

& The quantity of blowdown needed to ensure that

mit easy flow of noncondensable gases and associ-

the TDS level is kept below the recommended level

ated water vapor within the condenser. This requires

is determined by the TDS in the feed water, TDS to

adequate provision of venting system capacity taking

be maintained in the boiler and the evaporation

care of fluctuating operating vapor loads. At part load

rate.

operating conditions, for example, the venting equip-

ment capacity decreases as the condenser pressure & There are two types of blowdown, namely, intermit-

decreases. tent and continuous.

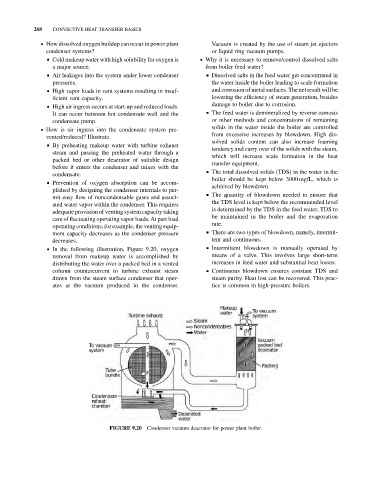

& In the following illustration, Figure 9.20, oxygen & Intermittent blowdown is manually operated by

removal from makeup water is accomplished by means of a valve. This involves large short-term

distributing the water over a packed bed in a vented increases in feed water and substantial heat losses.

column countercurrent to turbine exhaust steam & Continuous blowdown ensures constant TDS and

drawn from the steam surface condenser that oper- steam purity. Heat lost can be recovered. This prac-

ates at the vacuum produced in the condenser. tice is common in high-pressure boilers.

Condenser vacuum deaerator for power plant boiler.

FIGURE 9.20