Page 288 - Fluid mechanics, heat transfer, and mass transfer

P. 288

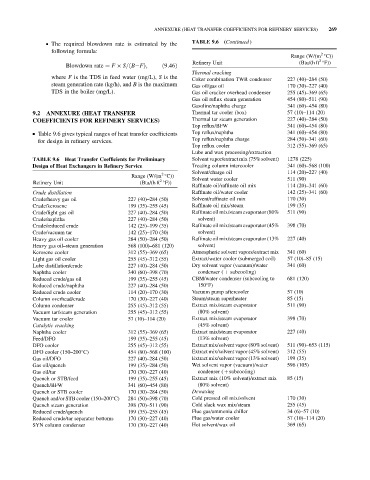

ANNEXURE (HEAT TRANSFER COEFFICIENTS FOR REFINERY SERVICES) 269

& The required blowdown rate is estimated by the TABLE 9.6 (Continued )

following formula:

2

Range (W/(m C))

2

Refinery Unit (Btu/(h ft F))

Blowdown rate ¼ F S=ðB FÞ; ð9:46Þ

Thermal cracking

where F is the TDS in feed water (mg/L), S is the

Coker combination TWR condenser 227 (40)–284 (50)

steam generation rate (kg/h), and B is the maximum Gas oil/gas oil 170 (30)–227 (40)

TDS in the boiler (mg/L). Gas oil cracker overhead condenser 255 (45)–369 (65)

Gas oil reflux steam generation 454 (80)–511 (90)

Gasoline/naphtha charge 341 (60)–454 (80)

Thermal tar cooler (box) 57 (10)–114 (20)

9.2 ANNEXURE (HEAT TRANSFER

Thermal tar steam generation 227 (40)–284 (50)

COEFFICIENTS FOR REFINERY SERVICES)

Top reflux/BFW 341 (60)–454 (80)

& Table 9.6 gives typical ranges of heat transfer coefficients Top reflux/naphtha 341 (60)–454 (80)

for design in refinery services. Top reflux/naphtha charge 284 (50)–341 (60)

Top reflux cooler 312 (55)–369 (65)

Lube and wax processing/extraction

Solvent vapor/extract mix (75% solvent) 1278 (225)

TABLE 9.6 Heat Transfer Coefficients for Preliminary

Treating column intercooler 341 (60)–568 (100)

Design of Heat Exchangers in Refinery Service

Solvent/charge oil 114 (20)–227 (40)

Range (W/(m C))

2

Solvent water cooler 511 (90)

2

Refinery Unit (Btu/(h ft F))

Raffinate oil/raffinate oil mix 114 (20)–341 (60)

Crude distillation Raffinate oil/water cooler 142 (25)–341 (60)

Crude/heavy gas oil 227 (40)–284 (50) Solvent/raffinate oil mix 170 (30)

Crude/kerosene 199 (35)–255 (45) Raffinate oil mix/steam 199 (35)

Crude/light gas oil 227 (40)–284 (50) Raffinate oil mix/steam evaporator (80% 511 (90)

Crude/naphtha 227 (40)–284 (50) solvent)

Crude/reduced crude 142 (25)–199 (35) Raffinate oil mix/steam evaporator (45% 398 (70)

Crude/vacuum tar 142 (25)–170 (30) solvent)

Heavy gas oil cooler 284 (50)–284 (50) Raffinate oil mix/steam evaporator (13% 227 (40)

Heavy gas oil–steam generation 568 (100)–681 (120) solvent)

Kerosene cooler 312 (55)–369 (65) Atmospheric solvent vapors/extract mix 341 (60)

Light gas oil cooler 255 (45)–312 (55) Extract/water cooler (submerged coil) 57 (10)–85 (15)

Lube distillation/crude 227 (40)–284 (50) Dry solvent vapor (vacuum)/water 341 (60)

Naphtha cooler 340 (60)–398 (70) condenser ( þ subcooling)

Reduced crude/gas oil 199 (35)–255 (45) CBM/water condenser (subcooling to 681 (120)

Reduced crude/naphtha 227 (40)–284 (50) 150 F)

Reduced crude cooler 114 (20)–170 (30) Vacuum pump aftercooler 57 (10)

Column overhead/crude 170 (30)–227 (40) Steam/steam superheater 85 (15)

Column condenser 255 (45)–312 (55) Extract mix/steam evaporator 511 (90)

Vacuum tar/steam generation 255 (45)–312 (55) (80% solvent)

Vacuum tar cooler 57 (10)–114 (20) Extract mix/steam evaporator 398 (70)

Catalytic cracking (45% solvent)

Naphtha cooler 312 (55)–369 (65) Extract mix/steam evaporator 227 (40)

Feed/DFO 199 (35)–255 (45) (13% solvent)

DFO cooler 255 (45)–312 (55) Extract mix/solvent vapor (80% solvent) 511 (90)–653 (115)

DFO cooler (150–200 C) 454 (80)–568 (100) Extract mix/solvent vapor (45% solvent) 312 (55)

Gas oil/DFO 227 (40)–284 (50) Extract mix/solvent vapor (13% solvent) 199 (35)

Gas oil/quench 199 (35)–284 (50) Wet solvent vapor (vacuum)/water 596 (105)

Gas oil/tar 170 (30)–227 (40) condenser ( þ subcooling)

Quench or STB/feed 199 (35)–255 (45) Extract mix (10% solvent)/extract mix 85 (15)

Quench/BFW 341 (60)–454 (80) (80% solvent)

Quench or STB cooler 170 (30)–284 (50) Dewaxing

Quench and/or STB cooler (150–200 C) 284 (50)–398 (70) Cold pressed oil mix/solvent 170 (30)

Quench steam generation 398 (70)–511 (90) Cold slack wax mix/steam 255 (45)

Reduced crude/quench 199 (35)–255 (45) Flue gas/ammonia chiller 34 (6)–57 (10)

Reduced crude/tar separator bottoms 170 (30)–227 (40) Flue gas/water cooler 57 (10)–114 (20)

SYN column condenser 170 (30)–227 (40) Hot solvent/wax oil 369 (65)