Page 292 - Fluid mechanics, heat transfer, and mass transfer

P. 292

HEAT EXCHANGERS 273

such fillers with liquid crystal polymers, their thermal where the inner pipes are connected in parallel, while

conductivities can be improved to the level of stain- the annuli are connected in series.

less steels. . What is meant by 1–2 and 2–4 exchangers? Show flow

& Their hydrophobic surfaces enhance dropwise arrangements for the above cases.

condensation. & 1–2 shell and tube heat exchanger means that it has

& Easy to join and seal. Good moldability. one shell pass and two tube passes (see Figure 10.4).

& A broad range of polymers is available to choose for The tube passes will be in multiples of two (1–2, 1–4,

different temperature ranges. Polyolefin materials 2–4, etc.).

are cost effectiveup to 90 C. Poly-ether-ether-ketone & Odd numbers of tube passes have more complicated

(PEEK) has a maximum operating temperature of mechanical stresses and so on. An exception is 1–1

220 C. exchangers that are sometimes used for vaporizers

& Polymeric exchangers are developed for applications and condensers (Figure 10.3).

involving concentration of acids and mechanical & 2–4 exchanger means that it has two shell passes and

vapor compression evaporators. four tube passes (Figure 10.5).

& Lower operating temperatures can be achieved to . Under what circumstances, a 1–2 heat exchanger is

make polymers suitable for heat transfer applica- recommended?

tions, for example, in evaporators by reducing & 1–2 exchangers involve moderate pressure drops

operating pressures. with reasonable fluid velocities and hence good heat

. What are the heat transfer areas for which a double pipe transfer coefficients on the tube side.

heat exchanger is suitable? . What are the important limitations of 1–1 exchangers?

& Double pipe heat exchangers may be a good choice & Low tube side fluid velocities and consequently not

2

2

for areas from 9.3 to 18.6 m (100–200 ft ). suitable for fouling fluids.

. ‘‘Double pipe heat exchanger is especially suitable for & Normally, being of fixed tube sheet construction, not

small heat transfer area surfaces and high tube pres- suitable for large temperature differences.

sures.’’ True/False?

. What is meant by TEMA? What are its functions?

& True.

& Tubular Exchanger Manufacturers Association

. What are the applications of double pipe heat exchan- (United States).

gers? What are their plus points? & TEMA standards are widely followed in the design

& Double pipe exchangers are extremely flexible with

and fabrication of shell and tube exchangers. These

respect to configuration of hairpin arrangements, standards cover the following main topics:

since both the inner pipes and annuli can be con- ➢ Nomenclature.

nected either in series or in parallel.

➢ Fabrication tolerances.

& In order to meet pressure drop constraints, it is

➢ Mechanical practices.

sometimes convenient to divide one stream into two

- Examples include required tube thicknesses for

or more parallel branches while leaving the other

different pressures, recommended gaskets, types

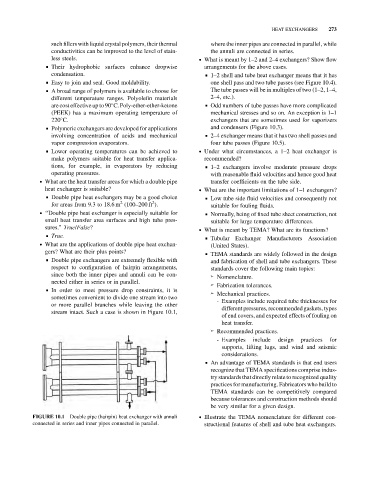

stream intact. Such a case is shown in Figure 10.1,

of end covers, and expected effects of fouling on

heat transfer.

➢ Recommended practices.

- Examples include design practices for

supports, lifting lugs, and wind and seismic

considerations.

& An advantage of TEMA standards is that end users

recognize that TEMA specifications comprise indus-

try standards that directly relate to recognized quality

practices for manufacturing. Fabricators who build to

TEMA standards can be competitively compared

because tolerances and construction methods should

be very similar for a given design.

Double pipe (hairpin) heat exchanger with annuli . Illustrate the TEMA nomenclature for different con-

FIGURE 10.1

connected in series and inner pipes connected in parallel. structional features of shell and tube heat exchangers.