Page 289 - Fluid mechanics, heat transfer, and mass transfer

P. 289

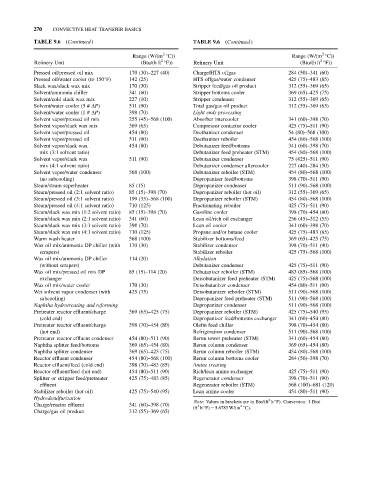

CONVECTIVE HEAT TRANSFER BASICS

270

(Continued ) TABLE 9.6 (Continued )

TABLE 9.6

Range (W/(m C)) Range (W/(m C))

2

2

Refinery Unit (Btu/(h ft F)) Refinery Unit (Btu/(h ft F))

2

2

Pressed oil/pressed oil mix 170 (30)–227 (40) Charge/HTS offgas 284 (50)–341 (60)

Pressed oil/water cooler (to 150 F) 142 (25) HTS offgas/water condenser 425 (75)–483 (85)

Slack wax/slack wax mix 170 (30) Stripper feed/gas oil product 312 (55)–369 (65)

Solvent/ammonia chiller 341 (60) Stripper bottoms cooler 369 (65)–425 (75)

Solvent/cold slack wax mix 227 (10) Stripper condenser 312 (55)–369 (65)

Solvent/water cooler (5 # DP) 511 (90) Total gas/gas oil product 312 (55)–369 (65)

Solvent/water cooler (1 # DP) 398 (70) Light ends processing

Solvent vapor/pressed oil mix 255 (45)–568 (100) Absorber intercooler 341 (60)–398 (70)

Solvent vapor/slack wax mix 369 (65) Compressor contactor cooler 425 (75)–511 (90)

Solvent vapor/pressed oil 454 (80) Deethanizer condenser 54 (80)–568 (100)

Solvent vapor/pressed oil 511 (90) Deethanizer reboiler 454 (80)–568 (100)

Solvent vapor/slack wax 454 (80) Debutanizer feed/bottoms 341 (60)–398 (70)

mix (3:1 solvent ratio) Debutanizer feed preheater (STM) 454 (80)–568 (100)

Solvent vapor/slack wax 511 (90) Debutanizer condenser 75 (425)–511 (90)

mix (4:1 solvent ratio) Debutanizer condenser aftercooler 227 (40)–284 (50)

Solvent vapor/water condenser 568 (100) Debutanizer reboiler (STM) 454 (80)–568 (100)

(no subcooling) Depropanizer feed/bottoms 398 (70)–511 (90)

Steam/steam superheater 85 (15) Depropanizer condenser 511 (90)–568 (100)

Steam/pressed oil (2:1 solvent ratio) 85 (15)–398 (70) Depropanizer reboiler (hot oil) 312 (55)–369 (65)

Steam/pressed oil (3:1 solvent ratio) 199 (35)–568 (100) Depropanizer reboiler (STM) 454 (80)–568 (100)

Steam/pressed oil (4:1 solvent ratio) 710 (125) Fractionating reboiler 425 (75)–511 (90)

Steam/slack wax mix (1:2 solvent ratio) 85 (15)–398 (70) Gasoline cooler 398 (70)–454 (80)

Steam/slack wax mix (2:1 solvent ratio) 341 (60) Lean oil/rich oil exchanger 256 (45)–312 (55)

Steam/slack wax mix (3:1 solvent ratio) 398 (70) Lean oil cooler 341 (60)–398 (70)

Steam/slack wax mix (4:1 solvent ratio) 710 (125) Propane and/or butane cooler 425 (75)–483 (85)

Warm wash heater 568 (100) Stabilizer bottoms/feed 369 (65)–425 (75)

Wax oil mix/ammonia DP chiller (with 170 (30) Stabilizer condenser 398 (70)–511 (90)

scrapers) Stabilizer reboiler 425 (75)–568 (100)

Wax oil mix/ammonia DP chiller 114 (20) Alkylation

(without scrapers) Debutanizer condenser 425 (75)–511 (90)

Wax oil mix/pressed oil mix DP 85 (15)–114 (20) Debutanizer reboiler (STM) 483 (85)–568 (100)

exchanger Deisobutanizer feed preheater (STM) 425 (75)–568 (100)

Wax oil mix/water cooler 170 (30) Deisobutanizer condenser 454 (80)–511 (90)

Wet solvent vapor condenser (with 425 (75) Deisobutanizer reboiler (STM) 511 (90)–568 (100)

subcooling) Depropanizer feed preheater (STM) 511 (90)–568 (100)

Naphtha hydrotreating and reforming Depropanizer condenser 511 (90)–568 (100)

Pretreater reactor effluent/charge 369 (65)–425 (75) Depropanizer reboiler (STM) 425 (75)–540 (95)

(cold end) Depropanizer feed/bottoms exchanger 341 (60)–454 (80)

Pretreater reactor effluent/charge 398 (70)–454 (80) Olefin feed chiller 398 (70)–454 (80)

(hot end) Refrigeration condenser 511 (90)–568 (100)

Pretreater reactor effluent condenser 454 (80)–511 (90) Rerun tower preheater (STM) 341 (60)–454 (80)

Naphtha splitter feed/bottoms 369 (65)–454 (80) Rerun column condenser 369 (65)–454 (80)

Naphtha splitter condenser 369 (65)–425 (75) Rerun column reboiler (STM) 454 (80)–568 (100)

Reactor effluent condenser 454 (80)–568 (100) Rerun column bottoms cooler 284 (50)–398 (70)

Reactor effluent/feed (cold end) 398 (70)–483 (85) Amine treating

Reactor effluent/feed (hot end) 454 (80)–511 (90) Rich/lean amine exchanger 425 (75)–511 (90)

Splitter or stripper feed/pretreater 425 (75)–483 (85) Regenerator condenser 398 (70)–511 (90)

effluent Regenerator reboiler (STM) 568 (100)–681 (120)

Stabilizer reboiler (hot oil) 425 (75)–540 (95) Lean amine cooler 454 (80)–511 (90)

Hydrodesulfurization

2

Note: Values in brackets are in Btu/(ft h F). Conversion: 1 Btu/

Charge/reactor effluent 341 (60)–398 (70) 2

(ft h F) ¼ 5.6785 W/(m C).

2

Charge/gas oil product 312 (55)–369 (65)