Page 264 - Forensic Structural Engineering Handbook

P. 264

8.4 CAUSES OF FAILURES

Space frame

Pipe hanger

Hinge

Stiffeners Bolts

Base plate

Micarta plate

Plates

Stiffeners Top chord of

steel truss

Truss vertical

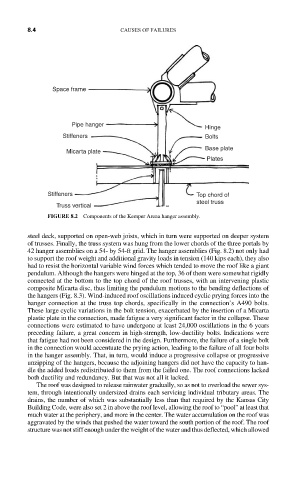

FIGURE 8.2 Components of the Kemper Arena hanger assembly.

steel deck, supported on open-web joists, which in turn were supported on deeper system

of trusses. Finally, the truss system was hung from the lower chords of the three portals by

42 hanger assemblies on a 54- by 54-ft grid. The hanger assemblies (Fig. 8.2) not only had

to support the roof weight and additional gravity loads in tension (140 kips each), they also

had to resist the horizontal variable wind forces which tended to move the roof like a giant

pendulum. Although the hangers were hinged at the top, 36 of them were somewhat rigidly

connected at the bottom to the top chord of the roof trusses, with an intervening plastic

composite Micarta disc, thus limiting the pendulum motions to the bending deflections of

the hangers (Fig. 8.3). Wind-induced roof oscillations induced cyclic prying forces into the

hanger connection at the truss top chords, specifically in the connection’s A490 bolts.

These large cyclic variations in the bolt tension, exacerbated by the insertion of a Micarta

plastic plate in the connection, made fatigue a very significant factor in the collapse. These

connections were estimated to have undergone at least 24,000 oscillations in the 6 years

preceding failure, a great concern in high-strength, low-ductility bolts. Indications were

that fatigue had not been considered in the design. Furthermore, the failure of a single bolt

in the connection would accentuate the prying action, leading to the failure of all four bolts

in the hanger assembly. That, in turn, would induce a progressive collapse or progressive

unzipping of the hangers, because the adjoining hangers did not have the capacity to han-

dle the added loads redistributed to them from the failed one. The roof connections lacked

both ductility and redundancy. But that was not all it lacked.

The roof was designed to release rainwater gradually, so as not to overload the sewer sys-

tem, through intentionally undersized drains each servicing individual tributary areas. The

drains, the number of which was substantially less than that required by the Kansas City

Building Code, were also set 2 in above the roof level, allowing the roof to “pool” at least that

much water at the periphery, and more in the center. The water accumulation on the roof was

aggravated by the winds that pushed the water toward the south portion of the roof. The roof

structure was not stiff enough under the weight of the water and thus deflected, which allowed