Page 108 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 108

Pump Best Practices Best Practice 2 .20

C a s e 1 2 3

N (speed) 3600 rpm 3600 rpm 3600 rpm

C (bearing 3000 3000 3000

dynamic load

factor – lbs)

F (total actual 170 500 1000

bearing load –

lbs)

Condition As designed Additional Additional

soft foot pipe load

forces forces

L-10 life years 25,495 hours 1002 hours 125 hours

Cause of early No early failure specified Excessive Excessive

failure minimum life was soft foot pipe load

exceeded forces forces

Note: use the relationship in Figure 2.20.7 to determine the

bearing L-10 life.

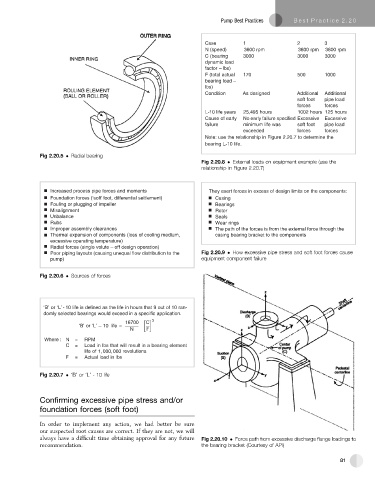

Fig 2.20.5 Radial bearing

Fig 2.20.8 External loads on equipment example (use the

relationship in Figure 2.20.7)

Increased process pipe forces and moments They exert forces in excess of design limits on the components:

Foundation forces (‘soft’ foot, differential settlement) Casing

Fouling or plugging of impeller Bearings

Misalignment Rotor

Unbalance Seals

Rubs Wear rings

Improper assembly clearances The path of the forces is from the external force through the

Thermal expansion of components (loss of cooling medium, casing bearing bracket to the components

excessive operating temperature)

Radial forces (single volute – off design operation)

Poor piping layouts (causing unequal flow distribution to the Fig 2.20.9 How excessive pipe stress and soft foot forces cause

pump) equipment component failure

Fig 2.20.6 Sources of forces

‘B’ or ‘L’ - 10 life is defined as the life in hours that 9 out of 10 ran-

domly selected bearings would exceed in a specific application.

16700 C 3

‘B’ or ‘L’ 10 life =

N F

Where : N = RPM

C = Load in lbs that will result in a bearing element

life of 1, 000, 000 revolutions

F = Actual load in lbs

Fig 2.20.7 ‘B’ or ‘L’ - 10 life

Confirming excessive pipe stress and/or

foundation forces (soft foot)

In order to implement any action, we had better be sure

our suspected root causes are correct. If they are not, we will

always have a difficult time obtaining approval for any future Fig 2.20.10 Force path from excessive discharge flange loadings to

recommendation. the bearing bracket (Courtesy of API)

81