Page 194 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 194

Be st Practice 3 .16 Compressor Best Practices

Best Practice 3.16Practice 3.16

Best

Use integral geared centrifugal compressors only for Lessons Learned

spared compressor applications. Un-spared integral geared compressors have lower re-

We do not recommend that un-spared integral geared compressors liability than between bearing centrifugal compressors

are used for un-spared process duty because: (95%) and greater MTTR due to their many components.

Integral gear centrifugal compressors were originally designed for I have been involved with many integral geared compressor failures

plant and instrument air services, which would use spared since the 1990s and have experienced the additional maintenance time

compressors. required to inspect and install bearings, seals and confirm acceptable

They are maintenance intensive since they use multiple bearings, gear mesh contact. Some clients have instituted a best practice not to

seals, gear meshes and operate at high speeds (above 50,000 RPM use un-spared integral geared compressors for process applications

for the last stage). including process air applications.

Because the gas is cooled after each impeller stage, their

performance characteristics and reliability are dependent on Benchmarks

intercooler condition. This best practice has been used since the 1990s and has successfully

Since they are typically supplied with only an overall surge convinced project teams not to use integral geared compressors for

protection system and not individual impeller stage protection, they un-spared process applications. Between bearing compressors were

are prone to surging if intercoolers do not attain design heat removal justified on the basis of optimum reliability (99.7%þ compared to 95%)

requirements.

and less mean time to repair (MTTR).

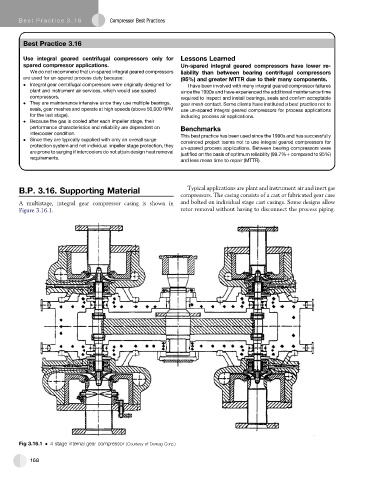

B.P. 3.16. Supporting Material Typical applications are plant and instrument air and inert gas

compressors. The casing consists of a cast or fabricated gear case

A multistage, integral gear compressor casing is shown in and bolted on individual stage cast casings. Some designs allow

Figure 3.16.1. rotor removal without having to disconnect the process piping.

Fig 3.16.1 4 stage internal gear compressor (Courtesy of Demag Corp.)

168