Page 261 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 261

Gear and Coupling Best Practices Be st Practice 4.3

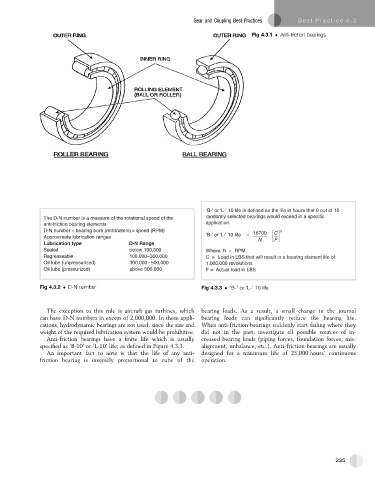

Fig 4.3.1 Anti-friction bearings

‘B-’ or ‘L-’ 10 life is defined as the life in hours that 9 out of 10

The D-N number is a measure of the rotational speed of the randomly selected bearings would exceed in a specific

anti-friction bearing elements application.

×

D-N number = bearing bore (millimeters) speed (RPM) 3

‘B-’ or ‘L-’ 10 life = 16700 C

Approximate lubrication ranges

N F

Lubrication type D-N Range

S e e l a d b o l e w 1 0 0 , 0 0 0 Where: N = RPM

R e e r g a s e a e l b 1 0 0 , 0 0 0–300,000 C = Load in LBS that will result in a bearing element life of

Oil lube (unpressurized) 300,000–500,000 1,000,000 revolutions

Oil lube (pressurized) above 500,000 F = Actual load in LBS

Fig 4.3.2 D-N number Fig 4.3.3 ‘B-’ or ‘L-’ 10 life

The exception to this rule is aircraft gas turbines, which bearing loads. As a result, a small change in the journal

can have D-N numbers in excess of 2,000,000. In these appli- bearing loads can significantly reduce the bearing life.

cations, hydrodynamic bearings are not used, since the size and When anti-friction bearings suddenly start failing where they

weight of the required lubrication system would be prohibitive. did not in the past, investigate all possible sources of in-

Anti-friction bearings have a finite life which is usually creased bearing loads (piping forces, foundation forces, mis-

specified as ‘B-10’ or ‘L-10’ life; as defined in Figure 4.3.3. alignment, unbalance, etc.). Anti-friction bearings are usually

An important fact to note is that the life of any anti- designed for a minimum life of 25,000 hours’ continuous

friction bearing is inversely proportional to cube of the operation.

235