Page 446 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 446

Lube, Seal and Control Oil System Best Practices Best Practice 7 .23

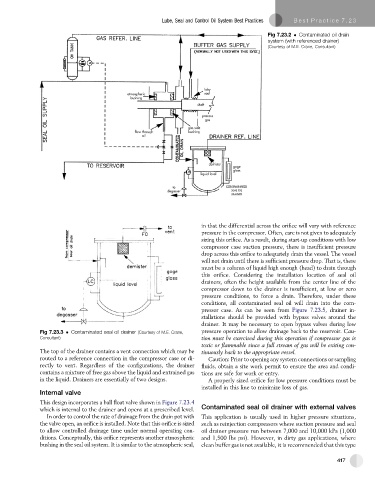

Fig 7.23.2 Contaminated oil drain

system (with referenced drainer)

(Courtesy of M.E. Crane, Consultant)

in that the differential across the orifice will vary with reference

pressure in the compressor. Often, care is not given to adequately

sizing this orifice. As a result, during start-up conditions with low

compressor case suction pressure, there is insufficient pressure

drop across this orifice to adequately drain the vessel. The vessel

will not drain until there is sufficientpressuredrop. That is, there

must be a column of liquid high enough (head) to drain through

this orifice. Considering the installation location of seal oil

drainers, often the height available from the center line of the

compressor down to the drainer is insufficient, at low or zero

pressure conditions, to force a drain. Therefore, under these

conditions, all contaminated seal oil will drain into the com-

pressor case. As can be seen from Figure 7.23.5, drainer in-

stallations should be provided with bypass valves around the

drainer. It may be necessary to open bypass valves during low

Fig 7.23.3 Contaminated seal oil drainer (Courtesy of M.E. Crane, pressure operation to allow drainage back to the reservoir. Cau-

Consultant)

tion must be exercised during this operation if compressor gas is

toxic or flammable since a full stream of gas will be exiting con-

The top of the drainer contains a vent connection which may be

tinuously back to the appropriate vessel.

routed to a reference connection in the compressor case or di- Caution: Prior to opening any system connections or sampling

rectly to vent. Regardless of the configurations, the drainer fluids, obtain a site work permit to ensure the area and condi-

contains a mixture of free gas above the liquid and entrained gas tions are safe for work or entry.

in the liquid. Drainers are essentially of two designs. A properly sized orifice for low pressure conditions must be

installed in this line to minimize loss of gas.

Internal valve

This design incorporates a ball float valve shown in Figure 7.23.4

which is internal to the drainer and opens at a prescribed level. Contaminated seal oil drainer with external valves

In order to control the rate of drainage from the drain pot with This application is usually used in higher pressure situations,

the valve open, an orifice is installed. Note that this orifice is sized such as reinjection compressors where suction pressure and seal

to allow controlled drainage time under normal operating con- oil drainer pressure run between 7,000 and 10,000 kPa (1,000

ditions. Conceptually, this orifice represents another atmospheric and 1,500 lbs psi). However, in dirty gas applications, where

bushing in the seal oil system. It is similar to the atmospheric seal, clean buffer gas is not available, it is recommended that this type

417