Page 450 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 450

Lube, Seal and Control Oil System Best Practices Best Practice 7 .23

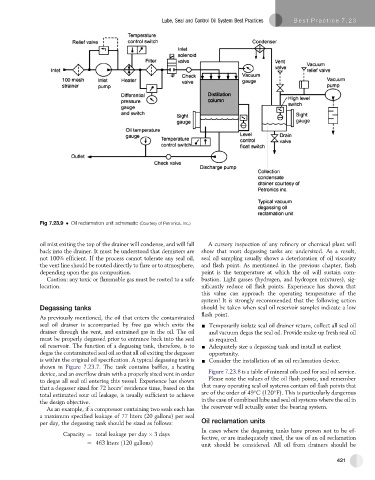

Fig 7.23.9 Oil reclamation unit schematic (Courtesy of Petronics, Inc.)

oil mist exiting the top of the drainer will condense, and will fall A cursory inspection of any refinery or chemical plant will

back into the drainer. It must be understood that demisters are show that most degassing tanks are undersized. As a result,

not 100% efficient. If the process cannot tolerate any seal oil, seal oil sampling usually shows a deterioration of oil viscosity

the vent line should be routed directly to flare or to atmosphere, and flash point. As mentioned in the previous chapter, flash

depending upon the gas composition. point is the temperature at which the oil will sustain com-

Caution: any toxic or flammable gas must be routed to a safe bustion. Light gasses (hydrogen, and hydrogen mixtures), sig-

location. nificantly reduce oil flash points. Experience has shown that

this value can approach the operating temperature of the

system! It is strongly recommended that the following action

Degassing tanks should be taken when seal oil reservoir samples indicate a low

flash point.

As previously mentioned, the oil that enters the contaminated

seal oil drainer is accompanied by free gas which exits the - Temporarily isolate seal oil drainer return, collect all seal oil

drainer through the vent, and entrained gas in the oil. The oil and vacuum degas the seal oil. Provide make up fresh seal oil

must be properly degassed prior to entrance back into the seal as required.

oil reservoir. The function of a degassing tank, therefore, is to - Adequately size a degassing tank and install at earliest

degas the contaminated seal oil so that all oil exiting the degasser opportunity.

is within the original oil specification. A typical degassing tank is - Consider the installation of an oil reclamation device.

shown in Figure 7.23.7. The tank contains baffles, a heating

device, and an overflow drain with a properly sized vent in order Figure 7.23.8 is a table of mineral oils used for seal oil service.

to degas all seal oil entering this vessel. Experience has shown Please note the values of the oil flash points, and remember

that a degasser sized for 72 hours’ residence time, based on the that many operating seal oil systems contain oil flash points that

are of the order of 49 C (120 F). This is particularly dangerous

total estimated sour oil leakage, is usually sufficient to achieve

the design objective. in the case of combined lube and seal oil systems where the oil in

As an example, if a compressor containing two seals each has the reservoir will actually enter the bearing system.

a maximum specified leakage of 77 liters (20 gallons) per seal

per day, the degassing tank should be sized as follows: Oil reclamation units

In cases where the degassing tanks have proven not to be ef-

Capacity ¼ total leakage per day 3 days

fective, or are inadequately sized, the use of an oil reclamation

¼ 463 liters ð120 gallonsÞ unit should be considered. All oil from drainers should be

421