Page 454 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 454

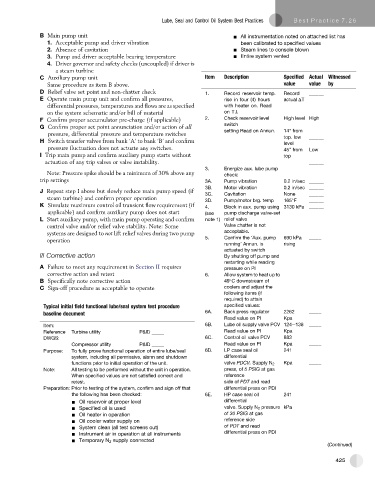

Lube, Seal and Control Oil System Best Practices Best Practice 7 .26

B Main pump unit - All instrumentation noted on attached list has

1. Acceptable pump and driver vibration been calibrated to specified values

2. Absence of cavitation - Steam lines to console blown

3. Pump and driver acceptable bearing temperature - Entire system vented

4. Driver governor and safety checks (uncoupled) if driver is

a steam turbine

C Auxiliary pump unit Item Description Specified Actual Witnessed

Same procedure as item B above. value value by

D Relief valve set point and non-chatter check 1. Record reservoir temp. Record ______

E Operate main pump unit and confirm all pressures, rise in four (4) hours actual DT

differential pressures, temperatures and flows are as specified with heater on. Read

on the system schematic and/or bill of material on T.I.

F Confirm proper accumulator pre-charge (if applicable) 2. Check reservoir level High level High

switch

G Confirm proper set point annunciation and/or action of all setting Read on Annun. 14" from

pressure, differential pressure and temperature switches

top. low ______

H Switch transfer valves from bank ‘A’ to bank ‘B’ and confirm level

pressure fluctuation does not actuate any switches. 45" from Low

I Trip main pump and confirm auxiliary pump starts without top

actuation of any trip valves or valve instability. ______

3. Energize aux. lube pump

Note: Pressure spike should be a minimum of 30% above any check:

trip settings 3A. Pump vibration 0.2 in/sec ______

3B. Motor vibration 0.2 in/sec ______

J Repeat step I above but slowly reduce main pump speed (if 3C. Cavitation None ______

steam turbine) and confirm proper operation

3D. Pump/motor brg. temp 165 F ______

K Simulate maximum control oil transient flow requirement (if 4. Block in aux. pump using 3130 kPa ______

applicable) and confirm auxiliary pump does not start (see pump discharge valve-set

L Start auxiliary pump, with main pump operating and confirm note 1) relief valve

control valve and/or relief valve stability. Note: Some Valve chatter is not

systems are designed to not lift relief valves during two pump acceptable.

5. Confirm the ‘Aux. pump 690 kPa _____

operation

running’ Annun. is rising

actuated by switch

III Corrective action By shutting off pump and

restarting while reading

A Failure to meet any requirement in Section II requires pressure on PI

corrective action and retest 6. Allow system to heat up to

B Specifically note corrective action 49 C downstream of

C Sign-off procedure as acceptable to operate coolers and adjust the

following items (if

required) to attain

Typical initial field functional lube/seal system test procedure specified values:

baseline document 6A. Back press regulator 2262 _____

Read value on PI Kpa

Item: 6B. Lube oil supply valve PCV 124e138 _____

Reference Turbine utility P&ID _____ Read value on PI Kpa

DWGS: 6C. Control oil valve PCV 883

Compressor utility P&ID _____ Read value on PI Kpa _____

Purpose: To fully prove functional operation of entire lube/seal 6D. LP case seal oil 241

system, including all permissive, alarm and shutdown differential

functions prior to initial operation of the unit. valve PDCV. Supply N 2 Kpa _____

Note: All testing to be performed without the unit in operation. press, of 5 PSIG at gas

When specified values are not satisfied correct and reference

retest. side of PDT and read

Preparation: Prior to testing of the system, confirm and sign off that differential press on PDI

the following has been checked: 6E. HP case seal oil 241

- Oil reservoir at proper level differential

- Specified oil is used valve. Supply N 2 pressure kPa

- Oil heater in operation of 30 PSIG at gas

- Oil cooler water supply on reference side

- System clean (all test screens out) of PDT and read

- Instrument air in operation at all instruments differential press on PDI

- Temporary N 2 supply connected

(Continued)

425