Page 459 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 459

Be st Practice 7 .29 Lube, Seal and Control Oil System Best Practices

lubrication oil supply, even in the event of failure of the stand-by and the bypass valve opens to control system pressure to

pump. a pre-set value, thereby bypassing excessive auxiliary pump

Such a system is useful in areas where an alternative form of (stand-by pump) flow. Upon starting of the critical equipment

energy is not available for main and spare pumps, as on platforms unit, the bypass valve will react to increasing main pump flow

or in chemical plants where a utility steam system is not and will gradually open to the point that it would be at maxi-

installed. mum stroke if the stand-by pump remained in operation. When

However, the system must still be designed to effectively lu- the stand-by pump is shut down, the response of the bypass

bricate all bearings prior to the main pump attaining full flow rate valve must be equal to the decrease of flow from the auxiliary

(speed). To facilitate this, the auxiliary pump is designed to start stand-by pump such that system pressure does not drop below

before the main critical equipment driver is started (permissive trip setting.

arrangement), and either automatically or manually shut off once Refer back to the concepts of an equivalent vessel and orifice

the shaft-driven pump attains sufficient speed. On shutdown, the discussed in previous sections. In this case, the supply to the

reverse occurs e the auxiliary pump will start on deceleration of equivalent vessel (from the auxiliary pump) instantaneously

the main pump. The signal to start the auxiliary pump can be drops while the demand from the critical equipment is constant

critical equipment speed or system pressure. If a system is not thus causing an instantaneous drop in equipment vessel pres-

designed for automatic shutoff of the auxiliary pump, care must sure. Prior to shutdown of the auxiliary pump, excessive supply

be taken to ensure that it is designed for continuous two-pump was recirculated by the bypass valve. Upon rapid decrease of

operation. It is recommended that auxiliary pumps be shut off supply flow, the bypass valve must decrease demand at the same

during critical equipment main pump operation. rate to ensure pressure in the system (equivalent vessel) is

A particular concern with this system design is to ensure maintained at a constant value. Failure to do this can result in

priming of the main pump. Frequently, the main pump is at critical equipment shutdown.

a significant height above the fluid reservoir. In this case, care

must be taken to ensure proper priming of main pump prior to Main and auxiliary A.C. motor-driven pumps,

start-up. Many systems incorporate a priming line from the

auxiliary pump to fill the main pump suction line. This requires D.C. motor-driven emergency pump

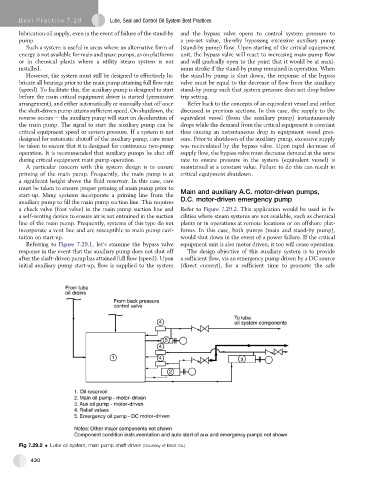

a check valve (foot valve) in the main pump suction line and Refer to Figure 7.29.2. This application would be used in fa-

a self-venting device to ensure air is not entrained in the suction cilities where steam systems are not available, such as chemical

line of the main pump. Frequently, systems of this type do not plants or in operations at remote locations or on offshore plat-

incorporate a vent line and are susceptible to main pump cavi- forms. In this case, both pumps (main and stand-by pump),

tation on start-up. would shut down in the event of a power failure. If the critical

Referring to Figure 7.29.1, let’s examine the bypass valve equipment unit is also motor driven, it too will cease operation.

response in the event that the auxiliary pump does not shut off The design objective of this auxiliary system is to provide

after the shaft-driven pump has attained full flow (speed). Upon a sufficient flow, via an emergency pump driven by a DC source

initial auxiliary pump start-up, flow is supplied to the system (direct current), for a sufficient time to promote the safe

Fig 7.29.2 Lube oil system, main pump shaft-driven (Courtesy of Elliott Co.)

430