Page 458 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 458

Lube, Seal and Control Oil System Best Practices Best Practice 7 .29

B.P. 7.28. Supporting Material

See B.P: 7.5 for supporting material.

Best

Best Practice 7.29Practice 7.29Practice 7.29

Best

Label oil system piping with colored tape to help personnel system. Failure to properly label piping, instruments and

to understand system operation and how to take correc- components leads to neglect and corresponding low oil

tive action quickly to prevent machinery unit trips. system reliability.

Color coded and identified oil system piping greatly increases site

personnel awareness of oil system operation. Benchmarks

Using colored tape to define each individual line of the system This best practice has been used since 2000 to increase understanding

(supply lines, return lines, bypass lines) involves personnel and pro- of oil system function and reliability of these systems. Operations,

motes ‘ownership’, thus increasing system safety and reliability. engineering and maintenance personnel, in many cases, have all par-

ticipated in the labeling and have shown increased interest in un-

Lessons Learned derstanding the system components function and local monitoring of

Many critical machine unit shutdowns are the result of not these components.

monitoring the local instrument and components in the

B.P. 7.29. Supporting Material Shaft-driven positive displacement main pump,

motor-driven auxiliary pump

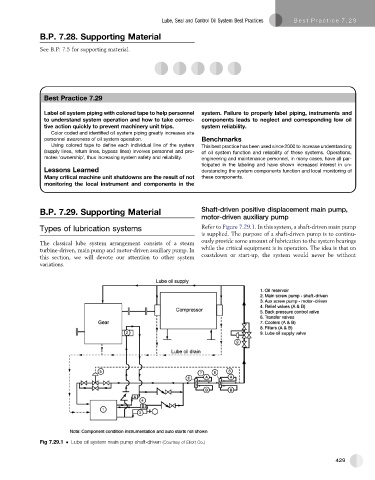

Types of lubrication systems Refer to Figure 7.29.1. In this system, a shaft-driven main pump

is supplied. The purpose of a shaft-driven pump is to continu-

The classical lube system arrangement consists of a steam ously provide some amount of lubrication to the system bearings

turbine-driven, main pump and motor-driven auxiliary pump. In while the critical equipment is in operation. The idea is that on

this section, we will devote our attention to other system coastdown or start-up, the system would never be without

variations.

Fig 7.29.1 Lube oil system main pump shaft-driven (Courtesy of Elliott Co.)

429