Page 54 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 54

Be st Practice 2 .2 Pump Best Practices

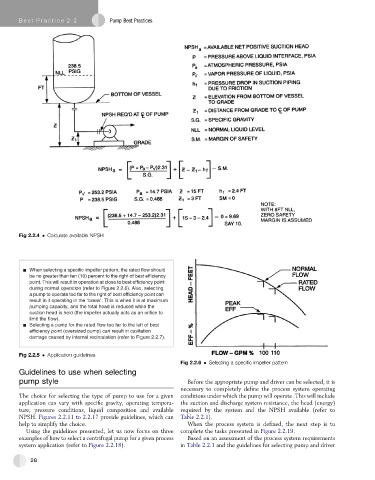

Fig 2.2.4 Calculate available NPSH

When selecting a specific impeller pattern, the rated flow should

be no greater than ten (10) percent to the right of best efficiency

point. This will result in operation at close to best efficiency point

during normal operation (refer to Figure 2.2.6). Also, selecting

a pump to operate too far to the right of best efficiency point can

result in it operating in the ‘break’. This is when it is at maximum

pumping capacity, and the total head is reduced while the

suction head is held (the impeller actually acts as an orifice to

limit the flow).

Selecting a pump for the rated flow too far to the left of best

efficiency point (oversized pump) can result in cavitation

damage caused by internal recirculation (refer to Figure 2.2.7).

Fig 2.2.5 Application guidelines

Fig 2.2.6 Selecting a specific impeller pattern

Guidelines to use when selecting

pump style Before the appropriate pump and driver can be selected, it is

necessary to completely define the process system operating

The choice for selecting the type of pump to use for a given conditions under which the pump will operate. This will include

application can vary with specific gravity, operating tempera- the suction and discharge system resistance, the head (energy)

ture, pressure conditions, liquid composition and available required by the system and the NPSH available (refer to

NPSH. Figures 2.2.11 to 2.2.17 provide guidelines, which can Table 2.2.1).

help to simplify the choice. When the process system is defined, the next step is to

Using the guidelines presented, let us now focus on three complete the tasks presented in Figure 2.2.19.

examples of how to select a centrifugal pump for a given process Based on an assessment of the process system requirements

system application (refer to Figure 2.2.18). in Table 2.2.1 and the guidelines for selecting pump and driver

28