Page 59 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 59

Pump Best Practices Be st Practice 2.3

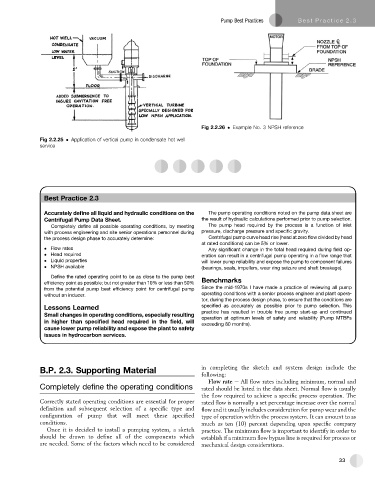

Fig 2.2.26 Example No. 3 NPSH reference

Fig 2.2.25 Application of vertical pump in condensate hot well

service

Best

Best Practice 2.3Practice 2.3

Accurately define all liquid and hydraulic conditions on the The pump operating conditions noted on the pump data sheet are

Centrifugal Pump Data Sheet. the result of hydraulic calculations performed prior to pump selection.

Completely define all possible operating conditions, by meeting The pump head required by the process is a function of inlet

with process engineering and site senior operations personnel during pressure, discharge pressure and specific gravity.

the process design phase to accurately determine: Centrifugal pump curve head rise (head at zero flow divided by head

at rated conditions) can be 5% or lower.

Flow rates Any significant change in the total head required during field op-

Head required eration can result in a centrifugal pump operating in a flow range that

Liquid properties will lower pump reliability and expose the pump to component failures

NPSH available (bearings, seals, impellers, wear ring seizure and shaft breakage).

Define the rated operating point to be as close to the pump best

efficiency point as possible; but not greater than 10% or less than 50% Benchmarks

from the potential pump best efficiency point for centrifugal pump Since the mid-1970s I have made a practice of reviewing all pump

without an inducer. operating conditions with a senior process engineer and plant opera-

tor, during the process design phase, to ensure that the conditions are

Lessons Learned specified as accurately as possible prior to pump selection. This

practice has resulted in trouble free pump start-up and continued

Small changes in operating conditions, especially resulting

operation at optimum levels of safety and reliability (Pump MTBFs

in higher than specified head required in the field, will

exceeding 80 months).

cause lower pump reliability and expose the plant to safety

issues in hydrocarbon services.

B.P. 2.3. Supporting Material in completing the sketch and system design include the

following:

Flow rate e All flow rates including minimum, normal and

Completely define the operating conditions rated should be listed in the data sheet. Normal flow is usually

the flow required to achieve a specific process operation. The

Correctly stated operating conditions are essential for proper rated flow is normally a set percentage increase over the normal

definition and subsequent selection of a specifictypeand flow and it usually includes consideration for pump wear and the

configuration of pump that will meet these specified type of operation within the process system. It can amount to as

conditions. much as ten (10) percent depending upon specific company

Once it is decided to install a pumping system, a sketch practice. The minimum flow is important to identify in order to

should be drawn to define all of the components which establish if a minimum flow bypass line is required for process or

are needed. Some of the factors which need to be considered mechanical design considerations.

33