Page 365 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 365

320 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

11.6.1 TURBINE FLOCCULATORS 1930s. They are widely used, especially in small plant situ-

3

ations e.g., 0.876 m =s (20 mgd) plant capacity. They are

The use of axial flow and turbine impellers of the Rushton

viewed with disfavor by some (Burns and Roe, 1971, pp. 4–6)

type (Sections 10.3.3.4, 10.4.2.5, and Glossary of Chapter 10)

because of lack of control of each of the unit processes. An

for flocculation was investigated by Walker (1968), then

additional disadvantage is that the flow of water is likely to be

president, Walker Process Equipment, who used a 1676 mm

distributed nonuniformly below the sludge blanket. The flow of

(66 in.) Rushton impeller in a 12.2 m (40 ft) diameter by 4.6 m water willseek its own path of least resistance through the sludge

(15 ft) tank with 1.52 m (5 ft) depth of submergence. The

blanket, thus creating a channel of higher velocity flow leaving

circulation patterns for the axial flow impeller was up and

much of the sludge blanket an inert mass. The advantage in

around with return flow to the impeller eye. While Walker

their use is that three unit processes, i.e., rapid mix, floccula-

was striving for uniform turbulence, the tests showed that the

tion, sedimentation, are combined in one unit with consequent

large eddies that predominated in the reactor volume were not

smaller size than the three unit processes as separate units.

efficient in flocculation, i.e., consistent with later theory.

11.6.2.1 Principles

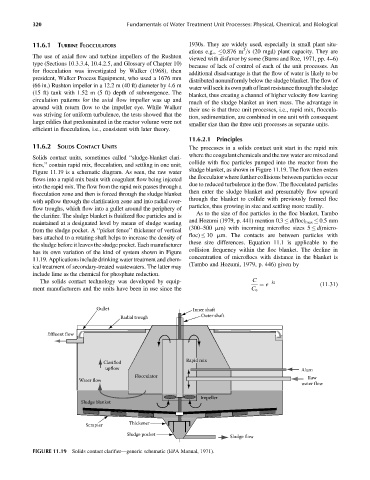

11.6.2 SOLIDS CONTACT UNITS The processes in a solids contact unit start in the rapid mix

where the coagulant chemicals and the raw water are mixed and

Solids contact units, sometimes called ‘‘sludge-blanket clari-

collide with floc particles pumped into the reactor from the

fiers,’’ contain rapid mix, flocculation, and settling in one unit;

sludge blanket, as shown in Figure 11.19. The flow then enters

Figure 11.19 is a schematic diagram. As seen, the raw water

the flocculator where further collisions between particles occur

flows into a rapid mix basin with coagulant flow being injected

due to reduced turbulence in the flow. The flocculated particles

into the rapid mix. The flow from the rapid mix passes through a

then enter the sludge blanket and presumably flow upward

flocculation zone and then is forced through the sludge blanket

through the blanket to collide with previously formed floc

with upflow through the clarification zone and into radial over-

particles, thus growing in size and settling more readily.

flow troughs, which flow into a gullet around the periphery of

As to the size of floc particles in the floc blanket, Tambo

the clarifier. The sludge blanket is fluidized floc particles and is

and Hozumi (1979, p. 441) mention 0.3 d(floc) max 0.5 mm

maintained at a designated level by means of sludge wasting

(300–500 mm) with incoming microfloc sizes 5 d(micro-

from the sludge pocket. A ‘‘picket fence’’ thickener of vertical

floc) 10 mm. The contacts are between particles with

bars attached to a rotating shaft helps to increase the density of

these size differences. Equation 11.1 is applicable to the

the sludge before it leaves the sludge pocket. Each manufacturer

collision frequency within the floc blanket. The decline in

has its own variation of the kind of system shown in Figure

concentration of microflocs with distance in the blanket is

11.19. Applications include drinking water treatment and chem-

(Tambo and Hozumi, 1979, p. 446) given by

ical treatment of secondary-treated wastewaters. The latter may

include lime as the chemical for phosphate reduction.

The solids contact technology was developed by equip- C kz

¼ e (11:31)

ment manufacturers and the units have been in use since the C o

Gullet Inner shaft

Radial trough Outer shaft

Effluent flow

Clarified Rapid mix

upflow Alum

Flocculator Raw

Water flow

water flow

Impeller

Sludge blanket

Scrapter Thickener

Sludge pocket

Sludge flow

FIGURE 11.19 Solids contact clarifier—generic schematic (EPA Manual, 1971).