Page 367 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 367

322 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

Required that of Table 11.6 except that the paddle-wheel diam-

Calculate the overflow velocity of a tank that will eter is to be 3.0 m instead of 3.9 m.

remove all particles larger than d(floc) 0.88 mm. Required

Reference is Section 11.4.2.1. Set up a design algorithm for four compartments.

11.4 Examples of G and u Parameters in Practice

Hint: Apply a trial-and-error solution using Table 11.6.

Given=Required 11.10 Design of Paddle-Wheel Flocculation System for a

For a nearby water treatment plant employing paddle Flotation System

wheel flocculators, calculate (a) G, (b) u, and (c) Gu.

Given

Do this for a full range of flow conditions, and sum-

A two-compartment flocculation basin is to be

marize in tabular form, and compare with values for 3

designed for Q ¼ 0.263 m =s (6.0 mgd) at T ¼ 208C

comparable plants in Table 11.1. What range in oper-

for a flotation system.

ator control is possible for G.

11.5 Floc Description Required

Set up a design algorithm with appropriate criteria for G.

Given=Required

Describe the floc formed at the different stages of the floc Hint: Apply a trial-and-error solution using Table

basin. Alternatively, describe the floc formed during a jar 11.10.

test at different times of rapid mix and flocculation. 11.11 Utilization of a P versus R Plot

11.6 Air Bubbles for Flocculation Given

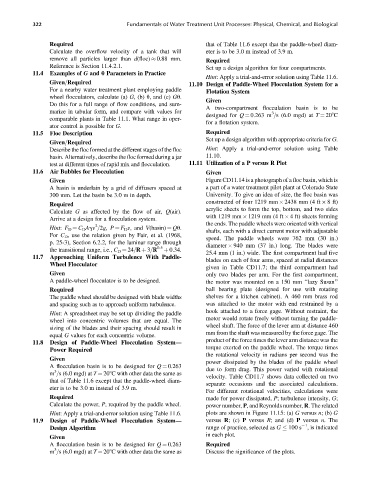

Given Figure CD11.14 is a photograph of a floc basin, which is

A basin is underlain by a grid of diffusers spaced at a part of a water treatment pilot plant at Colorado State

300 mm. Let the basin be 3.0 m in depth. University. To give an idea of size, the floc basin was

constructed of four 1219 mm 2438 mm (4 ft 8 ft)

Required

acrylic sheets to form the top, bottom, and two sides

Calculate G as affected by the flow of air, Q(air).

with 1219 mm 1219 mm (4 ft 4 ft) sheets forming

Arrive at a design for a flocculation system.

the ends. The paddle wheels were oriented with vertical

2

Hint: F D ¼ C D Agv =2g, P ¼ F D v,and V(basin) ¼ Qu.

shafts, each with a direct current motor with adjustable

For C D , use the relation given by Fair, et al. (1968,

speed. The paddle wheels were 762 mm (30 in.)

p. 25-3), Section 6.2.2, for the laminar range through diameter 940 mm (37 in.) long. The blades were

the transitional range, i.e., C D ¼ 24=R þ 3=R 0.5 þ 0.34.

25.4 mm (1 in.) wide. The first compartment had five

11.7 Approaching Uniform Turbulence With Paddle-

blades on each of four arms, spaced at radial distances

Wheel Flocculator

given in Table CD11.7; the third compartment had

Given only two blades per arm. For the first compartment,

A paddle-wheel flocculator is to be designed. the motor was mounted on a 150 mm ‘‘lazy Susan’’

Required ball bearing plate (designed for use with rotating

The paddle wheel should be designed with blade widths shelves for a kitchen cabinet). A 460 mm brass rod

and spacing such as to approach uniform turbulence. was attached to the motor with end restrained by a

hook attached to a force gage. Without restraint, the

Hint: A spreadsheet may be set up dividing the paddle

motor would rotate freely without turning the paddle-

wheel into concentric volumes that are equal. The

wheel shaft. The force of the lever arm at distance 460

sizing of the blades and their spacing should result in

mm from the shaft was measured by the force gage. The

equal G values for each concentric volume.

product of the force times the lever arm distance was the

11.8 Design of Paddle-Wheel Flocculation System—

torque exerted on the paddle wheel. The torque times

Power Required

the rotational velocity in radians per second was the

Given

power dissipated by the blades of the paddle wheel

A flocculation basin is to be designed for Q ¼ 0.263 due to form drag. This power varied with rotational

3

m =s (6.0 mgd) at T ¼ 208C with other data the same as

velocity. Table CD11.7 shows data collected on two

that of Table 11.6 except that the paddle-wheel diam-

separate occasions and the associated calculations.

eter is to be 3.0 m instead of 3.9 m.

For different rotational velocities, calculations were

Required made for power dissipated, P; turbulence intensity, G;

Calculate the power, P, required by the paddle wheel. power number, P, and Reynolds number, R. The related

Hint: Apply a trial-and-error solution using Table 11.6. plots are shown in Figure 11.15: (a) G versus n; (b) G

11.9 Design of Paddle-Wheel Flocculation System— versus R; (c) P versus R; and (d) P versus n. The

1

Design Algorithm range of practice, selected as G 100 s , is indicated

in each plot.

Given

A flocculation basin is to be designed for Q ¼ 0.263 Required

3

m =s (6.0 mgd) at T ¼ 208C with other data the same as Discuss the significance of the plots.