Page 609 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 609

564 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

Fire Conference

Laboratory Office

pump room

Hall

Lobby

Passage Electrical Shop Women Men Concentrate Raw water Permeate

Operations

Clear-well

F

P

F

Membranes P

F

P P P P De-gasing

P

Future Future Skid #3 Skid #2 Skid #1

skid #5 skid #4 Cleaning tanks

Chlorination cylinders

Acid Caustic

Passage Anti-scalant Passage Chlorination Passage Passage

scrubber

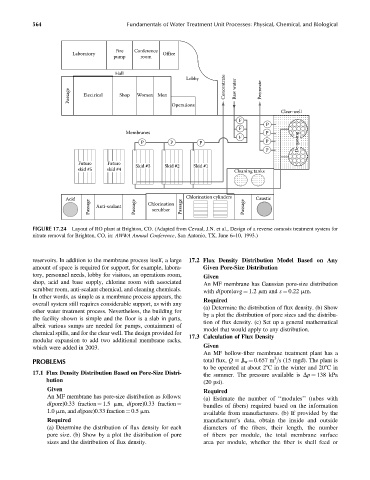

FIGURE 17.24 Layout of RO plant at Brighton, CO. (Adapted from Cevaal, J.N. et al., Design of a reverse osmosis treatment system for

nitrate removal for Brighton, CO, in: AWWA Annual Conference, San Antonio, TX, June 6–10, 1993.)

reservoirs. In addition to the membrane process itself, a large 17.2 Flux Density Distribution Model Based on Any

amount of space is required for support, for example, labora- Given Pore-Size Distribution

tory, personnel needs, lobby for visitors, an operations room, Given

shop, acid and base supply, chlorine room with associated An MF membrane has Gaussian pore-size distribution

scrubber room, anti-scalant chemical, and cleaning chemicals.

with d(pore)avg ¼ 1.2 mm and s ¼ 0.22 mm.

In other words, as simple as a membrane process appears, the

Required

overall system still requires considerable support, as with any

(a) Determine the distribution of flux density. (b) Show

other water treatment process. Nevertheless, the building for

by a plot the distribution of pore sizes and the distribu-

the facility shown is simple and the floor is a slab in parts,

tion of flux density. (c) Set up a general mathematical

albeit various sumps are needed for pumps, containment of

model that would apply to any distribution.

chemical spills, and for the clear well. The design provided for

17.3 Calculation of Flux Density

modular expansion to add two additional membrane racks,

which were added in 2003. Given

An MF hollow-fiber membrane treatment plant has a

3

PROBLEMS total flux, Q J w ¼ 0.657 m =s (15 mgd). The plant is

to be operated at about 28C in the winter and 208Cin

17.1 Flux Density Distribution Based on Pore-Size Distri- the summer. The pressure available is Dp ¼ 138 kPa

bution (20 psi).

Given Required

An MF membrane has pore-size distribution as follows: (a) Estimate the number of ‘‘modules’’ (tubes with

bundles of fibers) required based on the information

d(pore)0.33 fraction ¼ 1.5 mm, d(pore)0.33 fraction ¼

1.0 mm, and d(pore)0.33 fraction¼ 0.5 mm. available from manufacturers. (b) If provided by the

Required manufacturer’s data, obtain the inside and outside

(a) Determine the distribution of flux density for each diameters of the fibers, their length, the number

pore size. (b) Show by a plot the distribution of pore of fibers per module, the total membrane surface

sizes and the distribution of flux density. area per module, whether the fiber is shell feed or