Page 162 - Geothermal Energy Renewable Energy and The Environment

P. 162

148 Geothermal Energy: Renewable Energy and the Environment

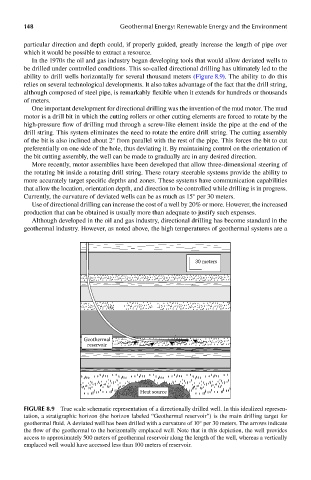

particular direction and depth could, if properly guided, greatly increase the length of pipe over

which it would be possible to extract a resource.

In the 1970s the oil and gas industry began developing tools that would allow deviated wells to

be drilled under controlled conditions. This so-called directional drilling has ultimately led to the

ability to drill wells horizontally for several thousand meters (Figure 8.9). The ability to do this

relies on several technological developments. It also takes advantage of the fact that the drill string,

although composed of steel pipe, is remarkably flexible when it extends for hundreds or thousands

of meters.

One important development for directional drilling was the invention of the mud motor. The mud

motor is a drill bit in which the cutting rollers or other cutting elements are forced to rotate by the

high-pressure flow of drilling mud through a screw-like element inside the pipe at the end of the

drill string. This system eliminates the need to rotate the entire drill string. The cutting assembly

of the bit is also inclined about 2° from parallel with the rest of the pipe. This forces the bit to cut

preferentially on one side of the hole, thus deviating it. By maintaining control on the orientation of

the bit cutting assembly, the well can be made to gradually arc in any desired direction.

More recently, motor assemblies have been developed that allow three-dimensional steering of

the rotating bit inside a rotating drill string. These rotary steerable systems provide the ability to

more accurately target specific depths and zones. These systems have communication capabilities

that allow the location, orientation depth, and direction to be controlled while drilling is in progress.

Currently, the curvature of deviated wells can be as much as 15° per 30 meters.

Use of directional drilling can increase the cost of a well by 20% or more. However, the increased

production that can be obtained is usually more than adequate to justify such expenses.

Although developed in the oil and gas industry, directional drilling has become standard in the

geothermal industry. However, as noted above, the high temperatures of geothermal systems are a

30 meters

Geothermal

reservoir

Heat source

FIGUre 8.9 True scale schematic representation of a directionally drilled well. In this idealized represen-

tation, a stratigraphic horizon (the horizon labeled “Geothermal reservoir”) is the main drilling target for

geothermal fluid. A deviated well has been drilled with a curvature of 10° per 30 meters. The arrows indicate

the flow of the geothermal to the horizontally emplaced well. Note that in this depiction, the well provides

access to approximately 500 meters of geothermal reservoir along the length of the well, whereas a vertically

emplaced well would have accessed less than 100 meters of reservoir.