Page 508 - Handbook of Thermal Analysis of Construction Materials

P. 508

480 Chapter 11 - Gypsum and Gypsum Products

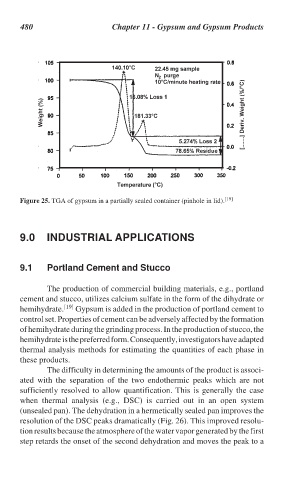

Figure 25. TGA of gypsum in a partially sealed container (pinhole in lid). [19]

9.0 INDUSTRIAL APPLICATIONS

9.1 Portland Cement and Stucco

The production of commercial building materials, e.g., portland

cement and stucco, utilizes calcium sulfate in the form of the dihydrate or

hemihydrate. [19] Gypsum is added in the production of portland cement to

control set. Properties of cement can be adversely affected by the formation

of hemihydrate during the grinding process. In the production of stucco, the

hemihydrate is the preferred form. Consequently, investigators have adapted

thermal analysis methods for estimating the quantities of each phase in

these products.

The difficulty in determining the amounts of the product is associ-

ated with the separation of the two endothermic peaks which are not

sufficiently resolved to allow quantification. This is generally the case

when thermal analysis (e.g., DSC) is carried out in an open system

(unsealed pan). The dehydration in a hermetically sealed pan improves the

resolution of the DSC peaks dramatically (Fig. 26). This improved resolu-

tion results because the atmosphere of the water vapor generated by the first

step retards the onset of the second dehydration and moves the peak to a