Page 29 - Handbook of Adhesion Promoters

P. 29

22 Mechanisms of Adhesion

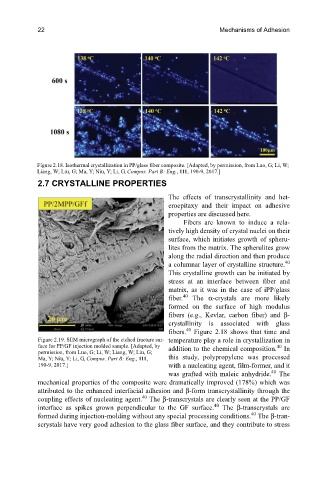

Figure 2.18. Isothermal crystallization in PP/glass fiber composite. [Adapted, by permission, from Luo, G; Li, W;

Liang, W; Liu, G; Ma, Y; Niu, Y; Li, G, Compos. Part B: Eng., 111, 190-9, 2017.]

2.7 CRYSTALLINE PROPERTIES

The effects of transcrystallinity and het-

eroepitaxy and their impact on adhesive

properties are discussed here.

Fibers are known to induce a rela-

tively high density of crystal nuclei on their

surface, which initiates growth of spheru-

lites from the matrix. The spherulites grow

along the radial direction and then produce

a columnar layer of crystalline structure. 40

This crystalline growth can be initiated by

stress at an interface between fiber and

matrix, as it was in the case of iPP/glass

40

fiber. The α-crystals are more likely

formed on the surface of high modulus

fibers (e.g., Kevlar, carbon fiber) and β-

crystallinity is associated with glass

40

fibers. Figure 2.18 shows that time and

Figure 2.19. SEM micrograph of the etched fracture sur- temperature play a role in crystallization in

face for PP/GF injection molded sample. [Adapted, by addition to the chemical composition. In

40

permission, from Luo, G; Li, W; Liang, W; Liu, G;

Ma, Y; Niu, Y; Li, G, Compos. Part B: Eng., 111, this study, polypropylene was processed

190-9, 2017.] with a nucleating agent, film-former, and it

40

was grafted with maleic anhydride. The

mechanical properties of the composite were dramatically improved (178%) which was

attributed to the enhanced interfacial adhesion and β-form transcrystallinity through the

40

coupling effects of nucleating agent. The β-transcrystals are clearly seen at the PP/GF

40

interface as spikes grown perpendicular to the GF surface. The β-transcrystals are

40

formed during injection-molding without any special processing conditions. The β-tran-

scrystals have very good adhesion to the glass fiber surface, and they contribute to stress