Page 375 - Handbook of Battery Materials

P. 375

346 12 Lithium Intercalation Cathode Materials for Lithium-Ion Batteries

E

LUMO µ a(Li)

E a

µ c(Li)

E g

FV oc

E c

HOMO

Cathode Anode

Electrolyte/separator

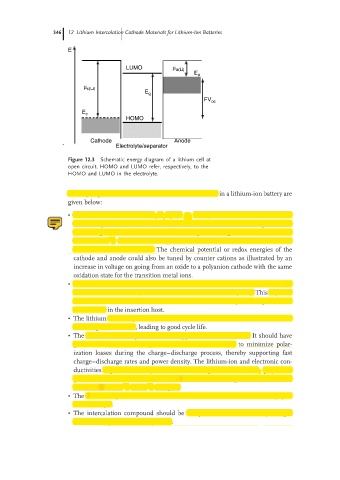

Figure 12.3 Schematic energy diagram of a lithium cell at

open circuit. HOMO and LUMO refer, respectively, to the

HOMO and LUMO in the electrolyte.

The key requirements for a successful cathode material in a lithium-ion battery are

given below:

• The intercalation cathode Li x M y X z (X = anion) should have a low lithium

chemical potential, and the intercalation anode should have a high lithium

chemical potential to maximize the cell voltage. This implies that the transition

metal ion M n+ should have a high oxidation state in the cathode and a low

oxidation state in the anode. The chemical potential or redox energies of the

cathode and anode could also be tuned by counter cations as illustrated by an

increase in voltage on going from an oxide to a polyanion cathode with the same

oxidation state for the transition metal ions.

• The intercalation compound should allow for insertion/extraction of a large

number of lithium ions per formula unit to maximize cell capacity. This depends

on the number of available lithium sites and the accessibility of multiple valence

states for M in the insertion host.

• The lithium insertion/extraction reaction should be reversible, with minimal or

no change in structure, leading to good cycle life.

• The intercalation compound should support mixed conduction. It should have

good electronic conductivity and lithium-ion conductivity to minimize polar-

ization losses during the charge–discharge process, thereby supporting fast

charge–discharge rates and power density. The lithium-ion and electronic con-

ductivities depend on the crystal structure, arrangement of the MX n polyhedral

geometry, interconnection of lithium sites, electronic configuration, and relative

positions of the M n+ and X n− energies.

• The redox energies of the cathode and anode should lie within the band gap of

the electrolyte.

• The intercalation compound should be inexpensive, environmentally benign,

and thermally and chemically stable.