Page 99 - Handbook of Civil Engineering Calculations, Second Edition

P. 99

1.82 STRUCTURAL STEEL ENGINEERING AND DESIGN

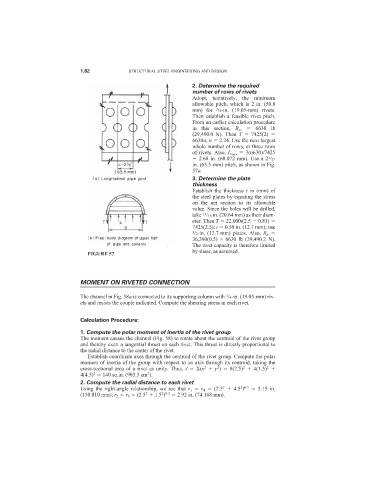

2. Determine the required

number of rows of rivets

Adopt, tentatively, the minimum

allowable pitch, which is 2 in. (50.8

mm) for /4-in. (19.05-mm) rivets.

3

Then establish a feasible rivet pitch.

From an earlier calculation procedure

in this section, R ss 6630 lb

(29,490.0 N). Then T 7425(2)

6630n; n 2.24. Use the next largest

whole number of rows, or three rows

of rivets. Also, L max 3(6630)/7425

1

2.68 in. (68.072 mm). Use a 2 /2-

in. (63.5-mm) pitch, as shown in Fig.

57a.

3. Determine the plate

thickness

Establish the thickness t in (mm) of

the steel plates by equating the stress

on the net section to its allowable

value. Since the holes will be drilled,

13

take /16 in. (20.64 mm) as their diam-

eter. Then T 22,000t(2.5 0.81)

7425(2.5); t 0.50 in. (12.7 mm); use

1 /2-in. (12.7-mm) plates. Also, R b

36,380(0.5) > 6630 lb (29,490.2 N).

The rivet capacity is therefore limited

by shear, as assumed.

FIGURE 57

MOMENT ON RIVETED CONNECTION

The channel in Fig. 58a is connected to its supporting column with /4-in. (19.05-mm) riv-

3

ets and resists the couple indicated. Compute the shearing stress in each rivet.

Calculation Procedure:

1. Compute the polar moment of inertia of the rivet group

The moment causes the channel (Fig. 58) to rotate about the centroid of the rivet group

and thereby exert a tangential thrust on each rivet. This thrust is directly proportional to

the radial distance to the center of the rivet.

Establish coordinate axes through the centroid of the rivet group. Compute the polar

moment of inertia of the group with respect to an axis through its centroid, taking the

2

2

2

2

cross-sectional area of a rivet as unity. Thus, J (x y ) 8(2.5) 4(1.5)

2

2

4(4.5) 140 sq.in. (903.3 cm ).

2. Compute the radial distance to each rivet

2 0.5

2

Using the right-angle relationship, we see that r 1 r 4 (2.5 4.5 ) 5.15 in.

2

2 0.5

(130.810 mm); r 2 r 3 (2.5 1.5 ) 2.92 in. (74.168 mm).