Page 408 - Handbook of Materials Failure Analysis

P. 408

406 CHAPTER 15 Welding-associated failures in power boilers

FIGURE 15.11

A schematic of the plug header in the aircooler [51].

Table 15.7 Chemical Composition of Studied Material (wt.%) [51]

Material C Mn Si S P Cr Ni Mo Nb N

15Mo3 0.130 0.77 0.22 0.10 0.009 - - 0.12 - -

1.4462 0.025 1.69 0.31 0.003 0.033 22 5.45 3.04 0.53 0.135

ER306Mo 0.34 1.49 0.40 0.012 - 24 14.2 2.74 0.13 -

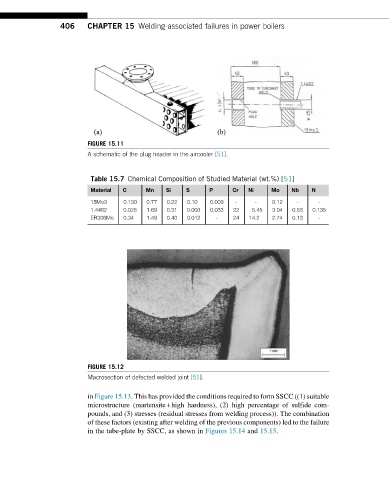

FIGURE 15.12

Macrosection of defected welded joint [51].

in Figure 15.13. This has provided the conditions required to form SSCC ((1) suitable

microstructure (martensite+high hardness), (2) high percentage of sulfide com-

pounds, and (3) stresses (residual stresses from welding process)). The combination

of these factors (existing after welding of the previous components) led to the failure

in the tube-plate by SSCC, as shown in Figures 15.14 and 15.15.