Page 175 - Handbook of Plastics Technologies

P. 175

THERMOSETS

THERMOSETS 3.45

FIGURE 3.39 Polyimides in general.

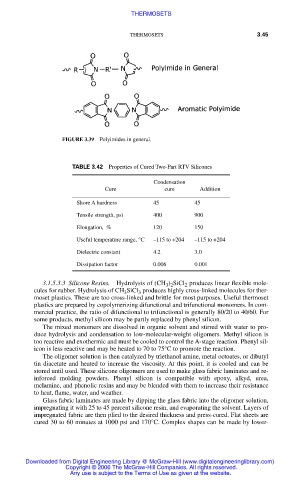

TABLE 3.42 Properties of Cured Two-Part RTV Silicones

Condensation

Cure cure Addition

Shore A hardness 45 45

Tensile strength, psi 400 900

Elongation, % 120 150

Useful temperature range, °C –115 to +204 –115 to +204

Dielectric constant 4.2 3.0

Dissipation factor 0.006 0.001

3.1.5.3.3 Silicone Resins. Hydrolysis of (CH ) SiCl produces linear flexible mole-

3 2

2

cules for rubber. Hydrolysis of CH SiCl produces highly cross-linked molecules for ther-

3

3

moset plastics. These are too cross-linked and brittle for most purposes. Useful thermoset

plastics are prepared by copolymerizing difunctional and trifunctional monomers. In com-

mercial practice, the ratio of difunctional to trifunctional is generally 80/20 to 40/60. For

some products, methyl silicon may be partly replaced by phenyl silicon.

The mixed monomers are dissolved in organic solvent and stirred with water to pro-

duce hydrolysis and condensation to low-molecular-weight oligomers. Methyl silicon is

too reactive and exothermic and must be cooled to control the A-stage reaction. Phenyl sil-

icon is less reactive and may be heated to 70 to 75°C to promote the reaction.

The oligomer solution is then catalyzed by triethanol amine, metal octoates, or dibutyl

tin diacetate and heated to increase the viscosity. At this point, it is cooled and can be

stored until used. These silicone oligomers are used to make glass fabric laminates and re-

inforced molding powders. Phenyl silicon is compatible with epoxy, alkyd, urea,

melamine, and phenolic resins and may be blended with them to increase their resistance

to heat, flame, water, and weather.

Glass fabric laminates are made by dipping the glass fabric into the oligomer solution,

impregnating it with 25 to 45 percent silicone resin, and evaporating the solvent. Layers of

impregnated fabric are then plied to the desired thickness and press-cured. Flat sheets are

cured 30 to 60 minutes at 1000 psi and 170°C. Complex shapes can be made by lower-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.