Page 177 - Handbook of Plastics Technologies

P. 177

THERMOSETS

THERMOSETS 3.47

been two persistent problems: (1) the syntheses are expensive, and (2) the molecular rigid-

ity that gives heat resistance also makes processing very difficult. The most successful

candidates so far have been the polyimides (Fig. 3.39).

Research has developed three synthetic routes to processability. (1) Thermoplastic

polyimides contain enough single bonds in the polymer backbone to provide a certain

amount of molecular flexibility and therefore processability. (2) Two-stage condensation

polymerization leaves single bonds in the first stage to permit processability and then

closes them to heterocyclic imide rings in the final stage of processing. (3) Second-stage

addition polymerization begins with synthesis of imide-containing vinyl or acetylenic

monomers in the first stage and then reacts the vinyl or acetylenic groups in the second

stage to produce cross-linking cure without liberating volatile by-products.

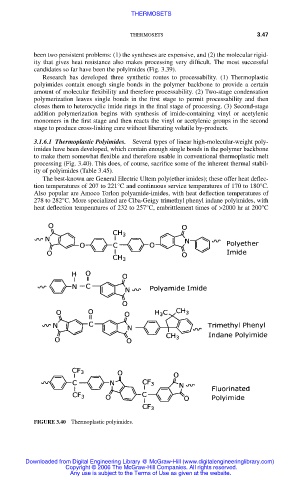

3.1.6.1 Thermoplastic Polyimides. Several types of linear high-molecular-weight poly-

imides have been developed, which contain enough single bonds in the polymer backbone

to make them somewhat flexible and therefore usable in conventional thermoplastic melt

processing (Fig. 3.40). This does, of course, sacrifice some of the inherent thermal stabil-

ity of polyimides (Table 3.45).

The best-known are General Electric Ultem poly(ether imides); these offer heat deflec-

tion temperatures of 207 to 221°C and continuous service temperatures of 170 to 180°C.

Also popular are Amoco Torlon polyamide-imides, with heat deflection temperatures of

278 to 282°C. More specialized are Ciba-Geigy trimethyl phenyl indane polyimides, with

heat deflection temperatures of 232 to 257°C, embrittlement times of >2000 hr at 200°C

FIGURE 3.40 Thermoplastic polyimides.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.