Page 181 - Handbook of Plastics Technologies

P. 181

THERMOSETS

THERMOSETS 3.51

TABLE 3.49 Skybond Polyimide Laminates

Flexural modulus, kpsi 3,120

335 hr/299°C 3,120

Flexural strength, kpsi 80

30 min/407°C 53

Tensile strength, kpsi 57

335 hr/299°C 42

Volume resistivity, Ω-cm 2.47 × 10 15

Dielectric constant 4.15

Dissipation factor 0.00445

Dilectric strength, V/mil 179

Water absorption, % 0.7

TABLE 3.50 Silicone Polyimide

Electrical Properties

17

Bulk resistivity 10 Ω-cm

Dielectric constant 3.0

Dielectric strength 5.5 MV/cm

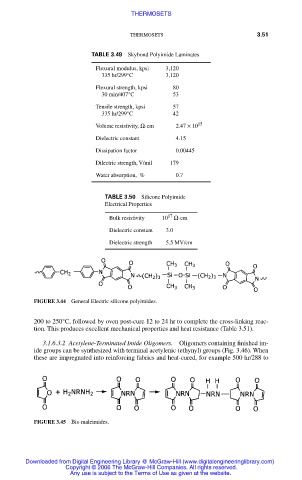

FIGURE 3.44 General Electric silicone polyimides.

200 to 250°C, followed by oven post-cure 12 to 24 hr to complete the cross-linking reac-

tion. This produces excellent mechanical properties and heat resistance (Table 3.51).

3.1.6.3.2 Acetylene-Terminated Imide Oligomers. Oligomers containing finished im-

ide groups can be synthesized with terminal acetylenic (ethynyl) groups (Fig. 3.46). When

these are impregnated into reinforcing fabrics and heat-cured, for example 500 hr/288 to

FIGURE 3.45 Bis-maleimides.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.