Page 179 - Handbook of Plastics Technologies

P. 179

THERMOSETS

THERMOSETS 3.49

TABLE 3.46 Kapton Polyimide Films

Density 1.42

Tensile modulus, kpsi, 23°C 430

200°C 260

Tensile strength, kpsi, 23°C 25

200°C 17

Elongation, %, 23°C 70

200°C 90

Impact strength, J/mm 23

Folding endurance, cycles 10,000

Initial tear strength, g 510

Tear propagation, g 8

Volume resistivity, Ω-cm 10 15

Dielectric constant 3.6

Dissipation factor 0.0025

Dielectric strength, V/mil 5,400

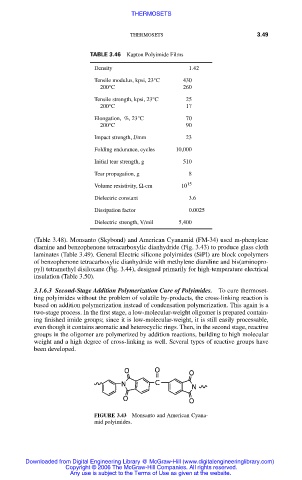

(Table 3.48). Monsanto (Skybond) and American Cyanamid (FM-34) used m-phenylene

diamine and benzophenone tetracarboxylic dianhydride (Fig. 3.43) to produce glass cloth

laminates (Table 3.49). General Electric silicone polyimides (SiPI) are block copolymers

of benzophenone tetracarboxylic dianhydride with methylene dianiline and bis(aminopro-

pyl) tetramethyl disiloxane (Fig. 3.44), designed primarily for high-temperature electrical

insulation (Table 3.50).

3.1.6.3 Second-Stage Addition Polymerization Cure of Polyimides. To cure thermoset-

ting polyimides without the problem of volatile by-products, the cross-linking reaction is

based on addition polymerization instead of condensation polymerization. This again is a

two-stage process. In the first stage, a low-molecular-weight oligomer is prepared contain-

ing finished imide groups; since it is low-molecular-weight, it is still easily processable,

even though it contains aromatic and heterocyclic rings. Then, in the second stage, reactive

groups in the oligomer are polymerized by addition reactions, building to high molecular

weight and a high degree of cross-linking as well. Several types of reactive groups have

been developed.

FIGURE 3.43 Monsanto and American Cyana-

mid polyimides.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.