Page 182 - Handbook of Plastics Technologies

P. 182

THERMOSETS

3.52 CHAPTER 3

TABLE 3.51 Bis-Maleimide Cured Properties

Flexural modulus, 25°C 4000 kpsi

250°C 3200 kpsi

Aged 3000 hr/250°C 2600 kpsi

Flexural strength, 25°C 70 kpsi

250°C 50 kpsi

Aged 3000 hr/250°C 26 kpsi

Tensile strength 50 kpsi

Compressive strength 50 kpsi

Notched impact strength 13 kpsi

T g 296°C

14

Volume resistivity 6 × 10 Ω-cm

Dielectric constant 4.5

Dissipation factor 0.012

Dielectric strength 25 kV/mm

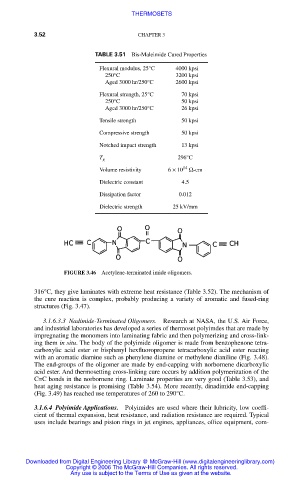

FIGURE 3.46 Acetylene-terminated imide oligomers.

316°C, they give laminates with extreme heat resistance (Table 3.52). The mechanism of

the cure reaction is complex, probably producing a variety of aromatic and fused-ring

structures (Fig. 3.47).

3.1.6.3.3 Nadimide-Terminated Oligomers. Research at NASA, the U.S. Air Force,

and industrial laboratories has developed a series of thermoset polyimdes that are made by

impregnating the monomers into laminating fabric and then polymerizing and cross-link-

ing them in situ. The body of the polyimide oligomer is made from benzophenone tetra-

carboxylic acid ester or bisphenyl hexfluoropropene tetracarboxylic acid ester reacting

with an aromatic diamine such as phenylene diamine or methylene dianiline (Fig. 3.48).

The end-groups of the oligomer are made by end-capping with norbornene dicarboxylic

acid ester. And thermosetting cross-linking cure occurs by addition polymerization of the

C=C bonds in the norbornene ring. Laminate properties are very good (Table 3.53), and

heat aging resistance is promising (Table 3.54). More recently, dinadimide end-capping

(Fig. 3.49) has reached use temperatures of 260 to 290°C.

3.1.6.4 Polyimide Applications. Polyimides are used where their lubricity, low coeffi-

cient of thermal expansion, heat resistance, and radiation resistance are required. Typical

uses include bearings and piston rings in jet engines, appliances, office equipment, com-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.