Page 233 - Handbook of Plastics Technologies

P. 233

ELASTOMERS

ELASTOMERS 4.25

breaking energy. Values of these properties increase with small amounts of cross-linking,

but they are reduced by further cross-link formation. Properties related to the energy to

break increase with increases in both the number of network chains and hysteresis. Since

hysteresis decreases as more network chains are developed, the energy-to-break related

properties are maximized at some intermediate cross-link density.

Reversion. Reversion is usually the loss of network structures by nonoxidative ther-

mal aging. It is generally associated with isoprene rubbers vulcanized by sulfur. It can be

the result a long vulcanization time (overcure) or of hot aging of thick sections. It is most

severe at temperatures above about 155°C. It occurs in vulcanizates containing large pro-

portions of polysulfidic cross-links. Sometimes the term “reversion” is applied to other

types of nonoxidative degradation, especially with respect to rubbers not based on iso-

prene. For example, thermal aging of SBR (styrene-butadiene rubber), which can cause in-

creased cross-link density and hardening, has been called reversion since it can be the

result of overcure.

4.5.1.2 Characterization of the Vulcanization Process. Important characteristics of the

vulcanization process are the time period before cross-linking starts, the rate of cross-link

formation once it starts, and the extent of cross-linking when the process ends. There must

be sufficient delay or scorch resistance (resistance to premature vulcanization or induction

period) to permit mixing, shaping, forming, and flowing in the mold, autoclave, or curing

oven before vulcanization begins. Then cross-link formation should be rapid and con-

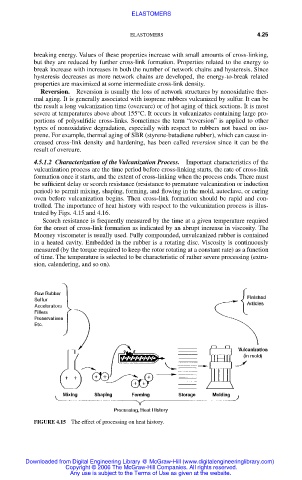

trolled. The importance of heat history with respect to the vulcanization process is illus-

trated by Figs. 4.15 and 4.16.

Scorch resistance is frequently measured by the time at a given temperature required

for the onset of cross-link formation as indicated by an abrupt increase in viscosity. The

Mooney viscometer is usually used. Fully compounded, unvulcanized rubber is contained

in a heated cavity. Embedded in the rubber is a rotating disc. Viscosity is continuously

measured (by the torque required to keep the rotor rotating at a constant rate) as a function

of time. The temperature is selected to be characteristic of rather severe processing (extru-

sion, calendering, and so on).

FIGURE 4.15 The effect of processing on heat history.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.