Page 241 - Handbook of Plastics Technologies

P. 241

ELASTOMERS

ELASTOMERS 4.33

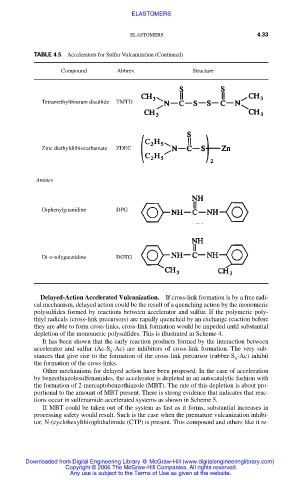

TABLE 4.5 Accelerators for Sulfur Vulcanization (Continued)

Compound Abbrev. Structure

Tetramethylthiuram disulfide TMTD

Zinc diethyldithiocarbamate ZDEC

Amines

Diphenylguanidine DPG

Di-o-tolyguanidine DOTG

Delayed-Action Accelerated Vulcanization. If cross-link formation is by a free radi-

cal mechanism, delayed action could be the result of a quenching action by the monomeric

polysulfides formed by reactions between accelerator and sulfur. If the polymeric poly-

thiyl radicals (cross-link precursors) are rapidly quenched by an exchange reaction before

they are able to form cross-links, cross-link formation would be impeded until substantial

depletion of the monomeric polysulfides. This is illustrated in Scheme 4.

It has been shown that the early reaction products formed by the interaction between

accelerator and sulfur (Ac-S -Ac) are inhibitors of cross-link formation. The very sub-

x

stances that give rise to the formation of the cross-link precursor (rubber-S -Ac) inhibit

x

the formation of the cross-links.

Other mechanisms for delayed action have been proposed. In the case of acceleration

by benzothiazolesulfenamides, the accelerator is depleted in an autocatalytic fashion with

the formation of 2-mercaptobenzothiazole (MBT). The rate of this depletion is about pro-

portional to the amount of MBT present. There is strong evidence that indicates that reac-

tions occur in sulfenamide-accelerated systems as shown in Scheme 5.

If MBT could be taken out of the system as fast as it forms, substantial increases in

processing safety would result. Such is the case when the premature vulcanization inhibi-

tor, N-(cyclohexylthio)phthalimide (CTP) is present. This compound and others like it re-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.