Page 246 - Handbook of Plastics Technologies

P. 246

ELASTOMERS

4.38 CHAPTER 4

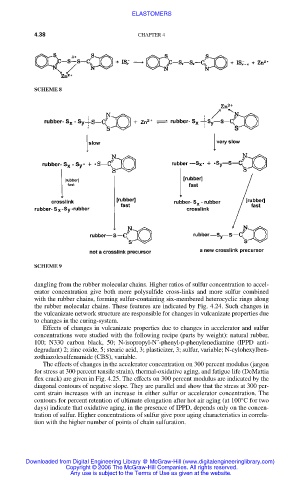

SCHEME 8

SCHEME 9

dangling from the rubber molecular chains. Higher ratios of sulfur concentration to accel-

erator concentration give both more polysulfide cross-links and more sulfur combined

with the rubber chains, forming sulfur-containing six-membered heterocyclic rings along

the rubber molecular chains. These features are indicated by Fig. 4.24. Such changes in

the vulcanizate network structure are responsible for changes in vulcanizate properties due

to changes in the curing-system.

Effects of changes in vulcanizate properties due to changes in accelerator and sulfur

concentrations were studied with the following recipe (parts by weight): natural rubber,

100; N330 carbon black, 50; N-isopropyl-N´-phenyl-p-phenylenediamine (IPPD anti-

degradant) 2; zinc oxide, 5; stearic acid, 3; plasticizer, 3; sulfur, variable; N-cylohexylben-

zothiazolesulfenamide (CBS), variable.

The effects of changes in the accelerator concentration on 300 percent modulus (jargon

for stress at 300 percent tensile strain), thermal-oxidative aging, and fatigue life (DeMattia

flex crack) are given in Fig. 4.25. The effects on 300 percent modulus are indicated by the

diagonal contours of negative slope. They are parallel and show that the stress at 300 per-

cent strain increases with an increase in either sulfur or accelerator concentration. The

contours for percent retention of ultimate elongation after hot air aging (at 100°C for two

days) indicate that oxidative aging, in the presence of IPPD, depends only on the concen-

tration of sulfur. Higher concentrations of sulfur give poor aging characteristics in correla-

tion with the higher number of points of chain sulfuration.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.