Page 260 - Handbook of Plastics Technologies

P. 260

ELASTOMERS

4.52 CHAPTER 4

Aromatic amines (e.g., N,N´-alkyl- or aryl-substituted p-phenylenediamines) find ap-

plication as both raw polymer stabilizers and also as final vulcanizate stabilizers. On the

other hand, phenolics (i.e., 2,6-dialkyl substituted) can be used in nonblack reinforced vul-

canizates where nonstaining and nondiscoloration are desired.

Examples of amine and phenolic-type antioxidants are given in Table 4.10.

In addition to the use of the above phenolic and amine type antioxidants, peroxide de-

composers are used to harmlessly decompose the peroxides, which otherwise could de-

compose to give free radical propagating species, e.g., R-O• or H-O•. Examples of such

peroxide decomposers, which act synergistically with the phenolic or amine antioxidants,

are dilauryl-β,β-thiodiproprionate and tris(p-nonylphenyl)phosphite. These and others are

also listed in Table 4.10, with their chemical structures being listed in Table 4.11. We note

that some of the peroxide decomposers are also accelerators for sulfur vulcanization.

4.5.2.3 Degradation by the Action of Ozone. The degradation of polydiene rubbers by

the action of atmospheric ozone is characterized by the appearance of cracks on the sur-

face of a finished rubber product. This degradation is caused by direct ozone attack and re-

action with the double bond sites of unsaturation in a polydiene rubber.

Early work established the following:

1. Ozone absorption occurs at a linear rate.

2. The absorption of ozone is proportional to its concentration.

3. Rubber that is not strained undergoes reaction with ozone to form oxidized film, but

it does not show the characteristic “ozone cracking.”

This last result was a key observation and has come to be known as the critical strain effect,

i.e., no crack growth occurs unless a specific strain for the particular polymer is exceeded.

Examples of rubbers that are thus affected include natural rubber (NR), synthetic cis-

polyisoprene, styrene-butadiene rubber (SBR), polybutadiene (BR), and nitrile rubber

(NBR). Rubbers with highly saturated backbones, such as ethylene-propylene-diene rub-

ber (EPDM) or halobutyl rubber (XllR), react very slowly with ozone and do not show this

cracking phenomenon. Typically, these ozone cracks develop in the polydiene elastomers

in a direction that is perpendicular to an applied stress. They are the result of rubber chain

scission and lead to the formation of several oxygen-containing decomposition products.

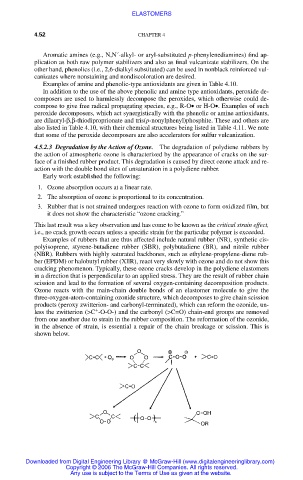

Ozone reacts with the main-chain double bonds of an elastomer molecule to give the

three-oxygen-atom-containing ozonide structure, which decomposes to give chain scission

products (peroxy zwitterion- and carbonyl-terminated), which can reform the ozonide, un-

+

less the zwitterion (>C -O-O-) and the carbonyl (>C=O) chain-end groups are removed

from one another due to strain in the rubber composition. The reformation of the ozonide,

in the absence of strain, is essential a repair of the chain breakage or scission. This is

shown below.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.