Page 54 - Handbook of Plastics Technologies

P. 54

INTRODUCTION TO POLYMERS AND PLASTICS

1.40 CHAPTER 1

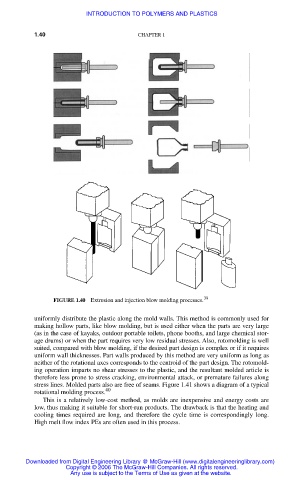

FIGURE 1.40 Extrusion and injection blow molding processes. 39

uniformly distribute the plastic along the mold walls. This method is commonly used for

making hollow parts, like blow molding, but is used either when the parts are very large

(as in the case of kayaks, outdoor portable toilets, phone booths, and large chemical stor-

age drums) or when the part requires very low residual stresses. Also, rotomolding is well

suited, compared with blow molding, if the desired part design is complex or if it requires

uniform wall thicknesses. Part walls produced by this method are very uniform as long as

neither of the rotational axes corresponds to the centroid of the part design. The rotomold-

ing operation imparts no shear stresses to the plastic, and the resultant molded article is

therefore less prone to stress cracking, environmental attack, or premature failures along

stress lines. Molded parts also are free of seams. Figure 1.41 shows a diagram of a typical

rotational molding process. 40

This is a relatively low-cost method, as molds are inexpensive and energy costs are

low, thus making it suitable for short-run products. The drawback is that the heating and

cooling times required are long, and therefore the cycle time is correspondingly long.

High melt flow index PEs are often used in this process.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.