Page 518 - Handbook of Properties of Textile and Technical Fibres

P. 518

Tensile failure of polyester fibers 491

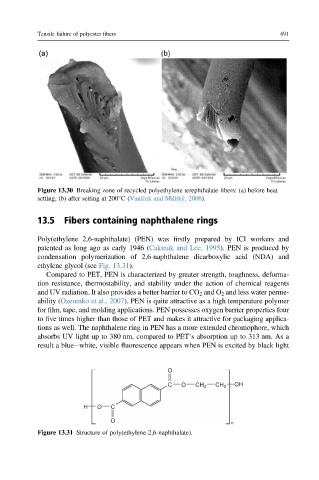

Figure 13.30 Breaking zone of recycled polyethylene terephthalate fibers: (a) before heat

setting, (b) after setting at 200 C(Vaní cek and Militký, 2006).

13.5 Fibers containing naphthalene rings

Poly(ethylene 2,6-naphthalate) (PEN) was firstly prepared by ICI workers and

patented as long ago as early 1946 (Cakmak and Lee, 1995). PEN is produced by

condensation polymerization of 2,6-naphthalene dicarboxylic acid (NDA) and

ethylene glycol (see Fig. 13.31).

Compared to PET, PEN is characterized by greater strength, toughness, deforma-

tion resistance, thermostability, and stability under the action of chemical reagents

and UV radiation. It also provides a better barrier to CO 2 and O 2 and less water perme-

ability (Ozerenko et al., 2007). PEN is quite attractive as a high temperature polymer

for film, tape, and molding applications. PEN possesses oxygen barrier properties four

to five times higher than those of PET and makes it attractive for packaging applica-

tions as well. The naphthalene ring in PEN has a more extended chromophore, which

absorbs UV light up to 380 nm, compared to PET’s absorption up to 313 nm. As a

result a blueewhite, visible fluorescence appears when PEN is excited by black light

O

C O CH 2 CH 2 OH

H O C

O

n

Figure 13.31 Structure of poly(ethylene-2,6-naphthalate).