Page 268 - Handbook of Structural Steel Connection Design and Details

P. 268

Welded Joint Design and Production

Welded Joint Design and Production 253

(both in thickness and in width). The rules regarding the addition of

supplemental fillet welds on shear tabs, currently a function of the

ratio of Z /Z, are very likely also inadequate and will require revision.

f

Until further research is done, the conservative approach is probably

to utilize welded web details. This does not preclude the use of a bolted

shear tab for erection purposes but would rely on welds as a singular

element connecting the web to the column.

Some of the alternate designs that have been contemplated after

the Northridge earthquake (see “Cover-Plated Designs”) increase the

moment capacity of the connection, reducing the requirement for the

web to transfer moment. These details are probably less sensitive to

the degree of interaction between welds and bolts.

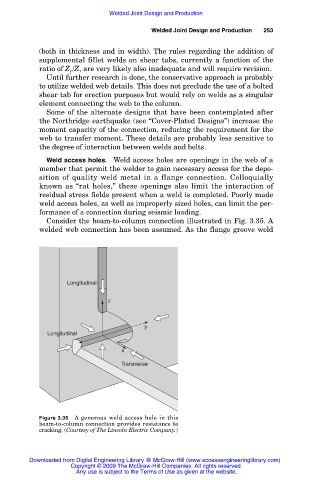

Weld access holes. Weld access holes are openings in the web of a

member that permit the welder to gain necessary access for the depo-

sition of quality weld metal in a flange connection. Colloquially

known as “rat holes,” these openings also limit the interaction of

residual stress fields present when a weld is completed. Poorly made

weld access holes, as well as improperly sized holes, can limit the per-

formance of a connection during seismic loading.

Consider the beam-to-column connection illustrated in Fig. 3.35. A

welded web connection has been assumed. As the flange groove weld

Longitudinal

z

y

Longitudinal

x

Transverse

Figure 3.35 A generous weld access hole in this

beam-to-column connection provides resistance to

cracking. (Courtesy of The Lincoln Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.