Page 263 - Handbook of Structural Steel Connection Design and Details

P. 263

Welded Joint Design and Production

248 Chapter Three

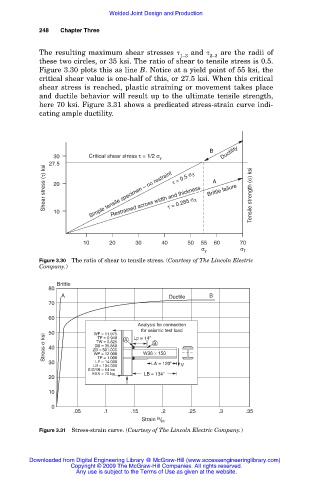

The resulting maximum shear stresses and are the radii of

1–3 2–3

these two circles, or 35 ksi. The ratio of shear to tensile stress is 0.5.

Figure 3.30 plots this as line B. Notice at a yield point of 55 ksi, the

critical shear value is one-half of this, or 27.5 ksi. When this critical

shear stress is reached, plastic straining or movement takes place

and ductile behavior will result up to the ultimate tensile strength,

here 70 ksi. Figure 3.31 shows a predicated stress-strain curve indi-

cating ample ductility.

B Ductility

30 Critical shear stress τ = 1/2 σ y

Shear stress (τ) ksi 27.5 Simple tensile specimen – no restraint τ = 0.285 σ 3 Brittle failure Tensile strength (σ) ksi

τ = 0.5 σ 3

A

20

Restrained across width and thickness

10

10 20 30 40 50 55 60 70

σ y σ T

Figure 3.30 The ratio of shear to tensile stress. (Courtesy of The Lincoln Electric

Company.)

Brittle

80

A Ductile B

70

60

Analysis for connection

for seismic test load

Stress σ ksi 50 ZB = 501.000 A Lp = 14" B

WF = 11.975

TF = 0.940

TW = 0.825

DB = 35.850

40

W36 × 150

WP = 12.000

TP = 1.000

30 LP = 14.000 LA = 120"

LB = 134.000 V

SIGYB = 54 ksi

EXX = 70 ksi LB = 134"

20

10

0

.05 .1 .15 .2 .25 .3 .35

Strain in / in

Figure 3.31 Stress-strain curve. (Courtesy of The Lincoln Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.