Page 260 - Handbook of Structural Steel Connection Design and Details

P. 260

Welded Joint Design and Production

Welded Joint Design and Production 245

Ductile hinges in connections. The fundamental premise regarding the

special moment-resisting frame (SMRF) is that plastic hinges will form

in the beams, absorbing seismically induced energies by inelastically

stretching and deforming the steel. The connection is not expected to

break. Following the Northridge earthquake, there was little or no evi-

dence of hinge formation. Instead, the connections or portions of the

connection experienced brittle fracture, inconsistent with expected and

essential behavior. Most of the ductility data are obtained from smooth,

slowly loaded, uniaxially loaded tensile specimens that are free to neck

down. If a notch is placed in the specimen, perpendicular to the applied

load, the specimen will be unable to exhibit its normal ductility, usually

measured as elongation. The presence of notchlike conditions in the

Northridge connections decreased the ductile behavior.

Initial research on SMRF connections conducted in the summer of

1994 attempted to eliminate the issues of notchlike conditions in the

test specimens by removing weld backing and weld tabs, and controlling

weld soundness. Even with these changes, “brittle” fractures occurred

when the standard details were tested. The testing program then evalu-

ated several modified details with short cover plates, with better suc-

cess. The reason for these differences can be explained analytically.

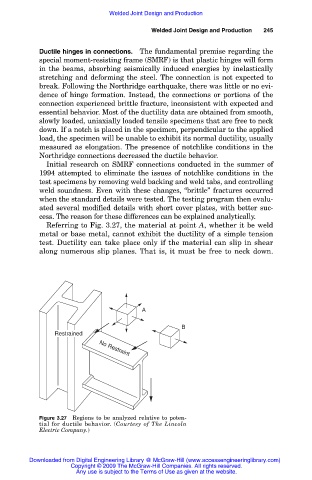

Referring to Fig. 3.27, the material at point A, whether it be weld

metal or base metal, cannot exhibit the ductility of a simple tension

test. Ductility can take place only if the material can slip in shear

along numerous slip planes. That is, it must be free to neck down.

A

B

Restrained No Restraint

Figure 3.27 Regions to be analyzed relative to poten-

tial for ductile behavior. (Courtesy of The Lincoln

Electric Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.