Page 265 - Handbook of Structural Steel Connection Design and Details

P. 265

Welded Joint Design and Production

250 Chapter Three

The solid-line circle in Fig. 3.33 is a plot of stresses for this condition.

The maximum shear stresses are 20 ksi. Notice that

1–3 2–3

these are less than the critical shear stress (27.5 ksi) so no plastic

movement, or ductility, would be expected.

In this case, the ratio of shear to tensile stress is 0.286. In Fig. 3.30,

this condition is plotted as line A. Notice it never exceeds the value of

the critical shear stress (27.5 ksi); therefore, there will be no plastic

strain or movement, and it will behave as a brittle material. Figure 3.31

shows a predicated stress-strain curve going upward as a straight

line A (elastic) until the ultimate tensile stress is reached in a brittle

manner with no energy absorbed plastically. It would therefore be

expected that, at the column face or in the weld where high restraint

exists, little ductility would be exhibited. This is where “brittle” frac-

tures have occurred, both in actual Northridge buildings and in labo-

ratory test specimens.

In the SMRF system, the greatest moment (due to lateral forces)

will occur at the column face. This moment must be resisted by the

beam’s section properties, which are lowest at the column face due to

weld access holes. Thus the highest stresses occur at this point, the

point where analysis shows ductility to be impossible.

In Fig. 3.27, material at point B was expected to behave as shown

in Fig. 3.29, and as line B in Fig. 3.30, and curve B in Fig. 3.31; that is,

with ample ductility. It is essential that plastic hinges be forced to

occur in this region.

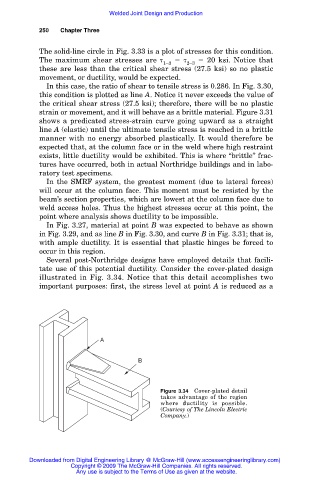

Several post-Northridge designs have employed details that facili-

tate use of this potential ductility. Consider the cover-plated design

illustrated in Fig. 3.34. Notice that this detail accomplishes two

important purposes: first, the stress level at point A is reduced as a

A

B

Figure 3.34 Cover-plated detail

takes advantage of the region

where ductility is possible.

(Courtesy of The Lincoln Electric

Company.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.