Page 34 - Handbook of Structural Steel Connection Design and Details

P. 34

Fasteners and Welds for Structural Connections

Fasteners and Welds for Structural Connections 19

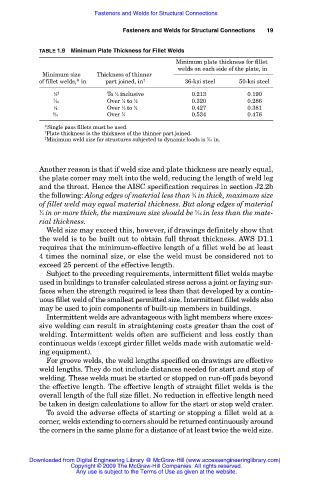

TABLE 1.9 Minimum Plate Thickness for Fillet Welds

Minimum plate thickness for fillet

welds on each side of the plate, in

Minimum size Thickness of thinner

of fillet welds,* in part joined, in † 36-ksi steel 50-ksi steel

1 ‡ To ⁄4 inclusive 0.213 0.190

1

⁄8

3 1 1 0.320 0.286

⁄16 Over ⁄4 to ⁄2

1 1 3 0.427 0.381

⁄4 Over ⁄2 to ⁄4

5 3 0.534 0.476

⁄16 Over ⁄4

*Single pass fillets must be used.

† Plate thickness is the thickness of the thinner part joined.

‡ Minimum weld size for structures subjected to dynamic loads is ⁄16 in.

3

Another reason is that if weld size and plate thickness are nearly equal,

the plate comer may melt into the weld, reducing the length of weld leg

and the throat. Hence the AISC specification requires in section J2.2b

1

the following: Along edges of material less than ⁄4 in thick, maximum size

of fillet weld may equal material thickness. But along edges of material

1 ⁄4 in or more thick, the maximum size should be ⁄16 in less than the mate-

1

rial thickness.

Weld size may exceed this, however, if drawings definitely show that

the weld is to be built out to obtain full throat thickness. AWS D1.1

requires that the minimum-effective length of a fillet weld be at least

4 times the nominal size, or else the weld must be considered not to

exceed 25 percent of the effective length.

Subject to the preceding requirements, intermittent fillet welds maybe

used in buildings to transfer calculated stress across a joint or faying sur-

faces when the strength required is less than that developed by a contin-

uous fillet weld of the smallest permitted size. Intermittent fillet welds also

may be used to join components of built-up members in buildings.

Intermittent welds are advantageous with light members where exces-

sive welding can result in straightening costs greater than the cost of

welding. Intermittent welds often are sufficient and less costly than

continuous welds (except girder fillet welds made with automatic weld-

ing equipment).

For groove welds, the weld lengths specified on drawings are effective

weld lengths. They do not include distances needed for start and stop of

welding. These welds must be started or stopped on run-off pads beyond

the effective length. The effective length of straight fillet welds is the

overall length of the full size fillet. No reduction in effective length need

be taken in design calculations to allow for the start or stop weld crater.

To avoid the adverse effects of starting or stopping a fillet weld at a

corner, welds extending to corners should be returned continuously around

the corners in the same plane for a distance of at least twice the weld size.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.