Page 31 - Handbook of Structural Steel Connection Design and Details

P. 31

Fasteners and Welds for Structural Connections

16 Chapter One

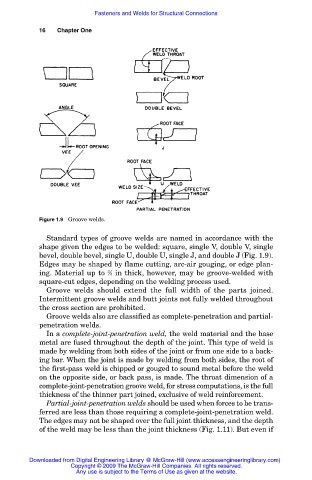

Figure 1.9 Groove welds.

Standard types of groove welds are named in accordance with the

shape given the edges to be welded: square, single V, double V, single

bevel, double bevel, single U, double U, single J, and double J (Fig. 1.9).

Edges may be shaped by flame cutting, arc-air gouging, or edge plan-

3

ing. Material up to ⁄8 in thick, however, may be groove-welded with

square-cut edges, depending on the welding process used.

Groove welds should extend the full width of the parts joined.

Intermittent groove welds and butt joints not fully welded throughout

the cross section are prohibited.

Groove welds also are classified as complete-penetration and partial-

penetration welds.

In a complete-joint-penetration weld, the weld material and the base

metal are fused throughout the depth of the joint. This type of weld is

made by welding from both sides of the joint or from one side to a back-

ing bar. When the joint is made by welding from both sides, the root of

the first-pass weld is chipped or gouged to sound metal before the weld

on the opposite side, or back pass, is made. The throat dimension of a

complete-joint-penetration groove weld, for stress computations, is the full

thickness of the thinner part joined, exclusive of weld reinforcement.

Partial-joint-penetration welds should be used when forces to be trans-

ferred are less than those requiring a complete-joint-penetration weld.

The edges may not be shaped over the full joint thickness, and the depth

of the weld may be less than the joint thickness (Fig. 1.11). But even if

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.