Page 26 - Handbook of Structural Steel Connection Design and Details

P. 26

Fasteners and Welds for Structural Connections

Fasteners and Welds for Structural Connections 11

Figure 1.4 Increasing the gage in

framing angles.

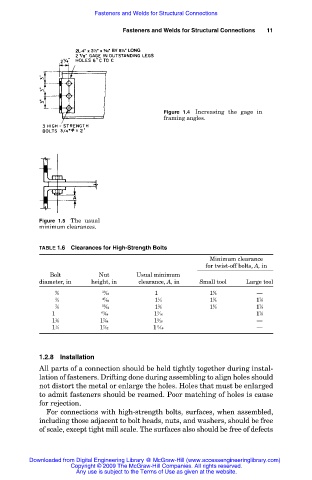

Figure 1.5 The usual

minimum clearances.

TABLE 1.6 Clearances for High-Strength Bolts

Minimum clearance

for twist-off bolts, A, in

Bolt Nut Usual minimum

diameter, in height, in clearance, A, in Small tool Large tool

5 39 1 5 —

1 ⁄8 1 ⁄64 1 ⁄8 1 ⁄8

3 47 1 5 7

1 ⁄4 1 ⁄64 1 ⁄4 1 ⁄8 1 ⁄8

7 55 3 5 7

1 ⁄8 1 ⁄64 1 ⁄8 1 ⁄8 1 ⁄8

1 63 7 7

1 ⁄8 ⁄64 1 ⁄16 1 ⁄8

1 7 9 —

1 ⁄8 1 ⁄64 1 ⁄16

1 7 11 —

1 ⁄4 1 ⁄32 1 ⁄16

1.2.8 Installation

All parts of a connection should be held tightly together during instal-

lation of fasteners. Drifting done during assembling to align holes should

not distort the metal or enlarge the holes. Holes that must be enlarged

to admit fasteners should be reamed. Poor matching of holes is cause

for rejection.

For connections with high-strength bolts, surfaces, when assembled,

including those adjacent to bolt heads, nuts, and washers, should be free

of scale, except tight mill scale. The surfaces also should be free of defects

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.