Page 30 - Handbook of Structural Steel Connection Design and Details

P. 30

Fasteners and Welds for Structural Connections

Fasteners and Welds for Structural Connections 15

More than one type of weld may be used in a connection. If so, the

allowable capacity of the connection is the sum of the effective capaci-

ties of each type of weld used, separately computed with respect to the

axis of the group.

Tack welds may be used for assembly or shipping. They are not

assigned any stress-carrying capacity in the final structure. In some

cases, these welds must be removed after final assembly or erection.

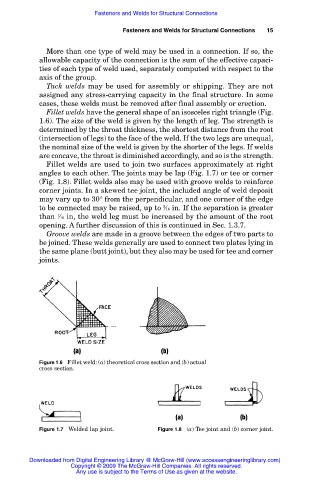

Fillet welds have the general shape of an isosceles right triangle (Fig.

1.6). The size of the weld is given by the length of leg. The strength is

determined by the throat thickness, the shortest distance from the root

(intersection of legs) to the face of the weld. If the two legs are unequal,

the nominal size of the weld is given by the shorter of the legs. If welds

are concave, the throat is diminished accordingly, and so is the strength.

Fillet welds are used to join two surfaces approximately at right

angles to each other. The joints may be lap (Fig. 1.7) or tee or corner

(Fig. 1.8). Fillet welds also may be used with groove welds to reinforce

corner joints. In a skewed tee joint, the included angle of weld deposit

may vary up to 30° from the perpendicular, and one corner of the edge

3

to be connected may be raised, up to ⁄16 in. If the separation is greater

than ⁄16 in, the weld leg must be increased by the amount of the root

1

opening. A further discussion of this is continued in Sec. 1.3.7.

Groove welds are made in a groove between the edges of two parts to

be joined. These welds generally are used to connect two plates lying in

the same plane (butt joint), but they also may be used for tee and corner

joints.

Figure 1.6 Fillet weld: (a) theoretical cross section and (b) actual

cross section.

Figure 1.7 Welded lap joint. Figure 1.8 (a) Tee joint and (b) corner joint.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.