Page 79 - Handbook of Surface Improvement and Modification

P. 79

74 Tackifiers

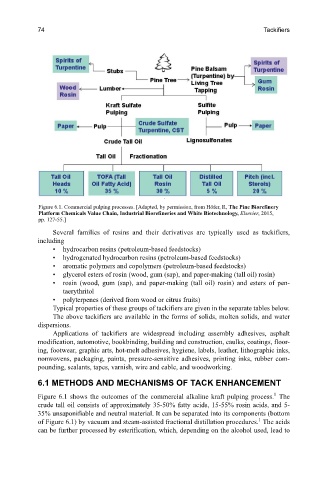

Figure 6.1. Commercial pulping processes. [Adapted, by permission, from Höfer, R, The Pine Biorefinery

Platform Chemicals Value Chain, Industrial Biorefineries and White Biotechnology, Elsevier, 2015,

pp. 127-55.]

Several families of resins and their derivatives are typically used as tackifiers,

including

• hydrocarbon resins (petroleum-based feedstocks)

• hydrogenated hydrocarbon resins (petroleum-based feedstocks)

• aromatic polymers and copolymers (petroleum-based feedstocks)

• glycerol esters of rosin (wood, gum (sap), and paper-making (tall oil) rosin)

• rosin (wood, gum (sap), and paper-making (tall oil) rosin) and esters of pen-

taerythritol

• polyterpenes (derived from wood or citrus fruits)

Typical properties of these groups of tackifiers are given in the separate tables below.

The above tackifiers are available in the forms of solids, molten solids, and water

dispersions.

Applications of tackifiers are widespread including assembly adhesives, asphalt

modification, automotive, bookbinding, building and construction, caulks, coatings, floor-

ing, footwear, graphic arts, hot-melt adhesives, hygiene, labels, leather, lithographic inks,

nonwovens, packaging, paints, pressure-sensitive adhesives, printing inks, rubber com-

pounding, sealants, tapes, varnish, wire and cable, and woodworking.

6.1 METHODS AND MECHANISMS OF TACK ENHANCEMENT

1

Figure 6.1 shows the outcomes of the commercial alkaline kraft pulping process. The

crude tall oil consists of approximately 35-50% fatty acids, 15-55% rosin acids, and 5-

35% unsaponifiable and neutral material. It can be separated into its components (bottom

1

of Figure 6.1) by vacuum and steam-assisted fractional distillation procedures. The acids

can be further processed by esterification, which, depending on the alcohol used, lead to